DTF transfers, or Direct-to-Film transfers, have emerged as a revolutionary method in the realm of custom apparel printing. This innovative printing technology boasts the capability of producing vibrant and durable designs suitable for a wide range of fabrics. As businesses and individuals increasingly seek to differentiate themselves through unique clothing and merchandise, understanding the merits of DTF transfers compared to traditional methods like sublimation and screen printing becomes essential. While sublimation offers beautiful color output, it is limited to polyester, whereas DTF can handle everything from cotton to blends, making it a versatile choice. In this exploration, we will delve deeper into DTF transfers, uncovering how they stand out within the landscape of modern printing techniques.

In the landscape of modern printing technologies, alternative techniques such as Direct-to-Film (DTF) printing are reshaping the custom apparel market. This approach utilizes a film transfer method that enables the application of intricate designs onto various fabrics, offering a level of versatility that many traditional methods lack. Whether you’re considering your options for custom designs on clothing or promotional items, understanding the distinctions between DTF, sublimation, and screen printing will guide you to making the best choice. The advancement of printing technology allows for direct application, ensuring durability and quality that can stand the test of time. This analysis will provide insights into how DTF compares to other popular custom printing methods, giving you the right information to elevate your apparel projects.

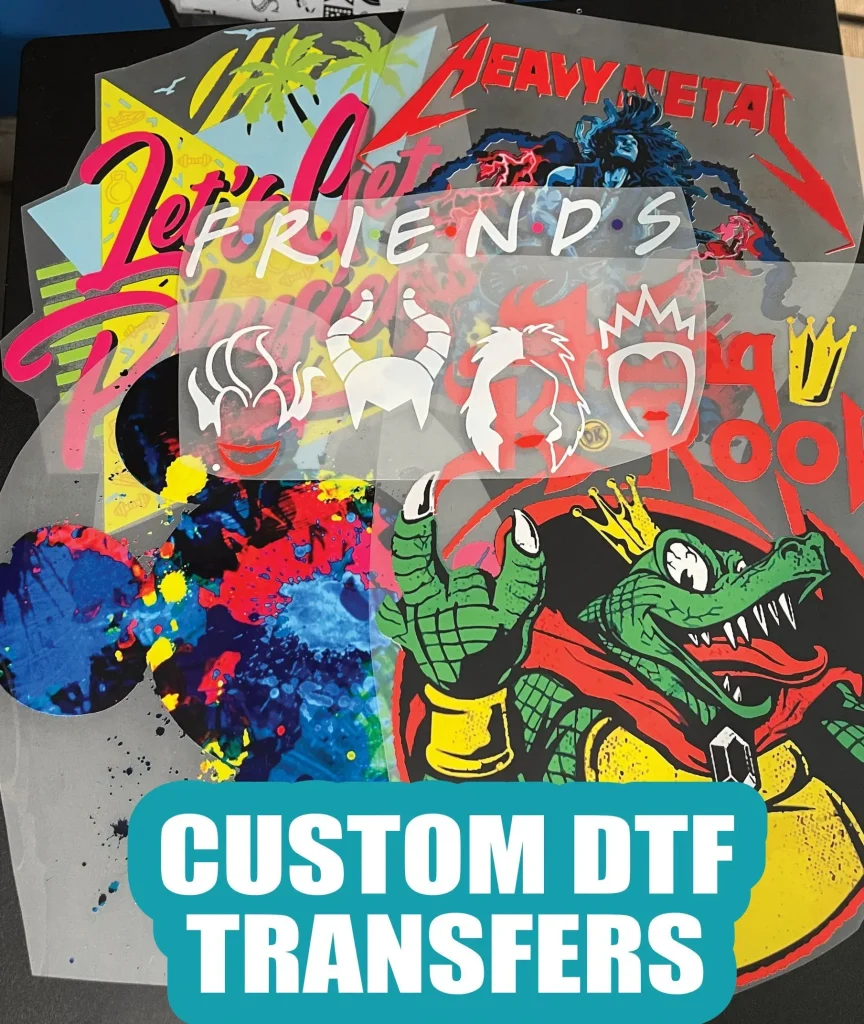

Understanding DTF Transfers in Apparel Printing

DTF transfers, or Direct-to-Film transfers, represent a revolutionary approach in the realm of apparel printing. This method utilizes a specialized film to accurately transfer vibrant designs directly onto various fabric types, sharply contrasting with traditional methods like screen printing and sublimation. For many artists and businesses, DTF has become a favored choice due to its versatility, allowing for printing on an extensive range of materials beyond just polyester. From cotton to blends, the flexibility offered by DTF transfers provides ample room for creative expression in custom apparel.

Moreover, the durability of DTF prints is another significant advantage. Unlike some printing methods that tend to fade or crack over time, DTF offers long-lasting results even after multiple washes. The high-quality finishes and resilience ensure that designs maintain their charm, making them ideal for custom merchandise and promotional items. As the demand for unique and personalized apparel grows, understanding DTF transfers’ capabilities is essential for those looking to thrive in the competitive world of custom printing.

Comparing DTF Transfers with Sublimation Printing

When navigating the different options in custom printing, comparing DTF transfers and sublimation printing is pivotal. While sublimation has long been synonymous with high-quality prints, its limitation to polyester fabrics significantly narrows design versatility. DTF printing, on the other hand, breaks these barriers, allowing designers to work with various fabrics including natural fibers. This flexibility is particularly beneficial for businesses aiming to cater to diverse customer preferences or those venturing into unique projects that require varied material combinations.

In addition to fabric versatility, the application methods differ for both techniques. Sublimation involves a heat application process that vaporizes the dye to bond with the material at the molecular level. Conversely, DTF utilizes a straightforward heat-press method that does not require the fabric to be synthetic, leading to a more user-friendly experience. This simplified application process makes DTF not only accessible to large-scale operations but also appealing to hobbyists and small business owners looking for effective and efficient printing solutions.

DTF Transfers vs. Screen Printing: A Cost-Effectiveness Analysis

Screen printing has traditionally dominated the landscape of custom apparel printing, especially for bulk orders due to its cost-effectiveness at scale. However, when analyzing startup costs for smaller projects, DTF transfers may emerge as the more economical option. DTF does not necessitate the creation of separate screens for different colors, making it far less expensive for intricate and multi-colored designs, especially when producing low volumes. This aspect makes DTF increasingly attractive for startups and individual designers.

Moreover, DTF printing accommodates a wide array of design complexities without incurring additional costs associated with screen printing. Creators can produce detailed designs with smooth gradients and various color combinations without lengthy setup times or additional fees per color, unlike screen printing. Ultimately, the ability to offer unique, multi-color designs on demand makes DTF an appealing solution for those looking to innovate within the apparel printing sector.

Recent Developments in DTF Printing Technology

The landscape of DTF transfers has seen significant advancement, with companies constantly innovating to improve accessibility and efficiency. For instance, dedicated DTF services are cropping up with a focus on offering high-quality transfers alongside rapid turnaround times. Businesses like Sam’s DTF Transfers have positioned themselves as leaders by catering to both small entrepreneurs seeking quick solutions and larger printers that demand high-volume production. These developments signal a robust growth trajectory for DTF technology in the custom printing ecosystem.

Additionally, the introduction of user-friendly custom transfer solutions has democratized access to DTF printing. Creators can effortlessly design and produce full-color transfers, empowering both seasoned professionals and newcomers alike. This democratization allows for a blossoming of creativity in custom apparel as more people can experiment and innovate without the barriers traditionally associated with printing technology. Keeping abreast of these innovations is now essential for anyone engaged in the custom printing industry, as they adapt to the evolving needs of their clientele.

Craftroom Essentials for DTF Printing Projects

As more crafters turn toward DTF printing, it’s essential to understand the craftroom essentials that make this process smooth and efficient. At its core, a high-quality heat press is imperative for transferring DTF designs onto fabric accurately. Furthermore, investing in the right film and inks compatible with DTF technology is crucial for achieving those brilliant, vibrant results that this method is known for. Upgrading craft supplies tailored for DTF can significantly enhance the outcome of custom apparel projects.

Additionally, understanding the specific maintenance and operation of a DTF system is vital for anyone starting. Regular upkeep of the heat press and ensuring proper storage of films and inks can drastically affect printing quality. Crafters should also familiarize themselves with DTF software and design tools to optimize their prints, ultimately leading to a satisfying crafting experience and successful end products that stand the test of time. With the right setup, DTF printing can transform craftrooms into creative havens.

Making Informed Decisions in Custom Printing

Deciding between DTF transfers, sublimation, and screen printing requires a comprehensive understanding of each method’s strengths and limitations. This careful consideration is vital for businesses and crafters as they aim to produce high-quality, custom designs for their target audience. For projects demanding versatility and color vibrancy across various fabric types, DTF printing invariably emerges as a strong contender. Its ease of use and minimal costs associated with small runs further highlight its appeal in competitive markets.

Ultimately, the decision comes down to the specific needs of the project. As the custom printing industry evolves, remaining informed about each technology’s latest developments can lead to strategic advantages in production and market reach. By leveraging their unique capabilities and adaptability, creators can ensure their choice aligns with their artistic vision and business goals, paving the way for innovation within the custom apparel landscape.

Frequently Asked Questions

What are the benefits of using DTF transfers in custom apparel printing?

DTF transfers offer several benefits in custom apparel printing. They are versatile, capable of printing on a variety of fabrics including cotton and polyester. DTF printing is also cost-effective for smaller runs, as it eliminates the need for multiple screens. Additionally, the vibrancy and durability of DTF prints ensure that designs remain intact after multiple washes.

How does DTF printing compare to sublimation printing?

DTF printing differs significantly from sublimation printing in that it can be applied to a wider range of fabrics, including cotton, while sublimation is limited to polyester. The DTF process involves transferring designs using a heat press, which is simpler compared to the gas infusion method used in sublimation, making DTF a more versatile option for custom printing.

Is DTF transfer printing more cost-effective than screen printing?

Yes, DTF transfer printing is often more cost-effective for small projects when compared to screen printing. While screen printing requires significant setup costs for multiple colors and bulk orders, DTF printing simplifies the process, making it ideal for low-volume orders or intricate designs without the need for multiple screens.

What types of projects are best suited for DTF transfers?

DTF transfers are best suited for projects that involve multi-color designs or intricate patterns. They are an excellent choice for small businesses or individual creators looking to produce high-quality custom apparel without the complications associated with traditional methods like screen printing or sublimation.

Can I achieve high-quality prints with DTF transfers?

Absolutely! DTF transfers produce high-quality, vibrant images that are durable and withstand multiple washes without fading. The technology behind DTF printing allows for detailed color gradients and intricate designs, making it a reliable choice for custom apparel printing.

Are there innovations in DTF printing technology that make it easier for users?

Yes, recent advancements in DTF printing technology have introduced user-friendly solutions. Companies have developed dedicated DTF services that offer high-quality prints with quick turnaround times. These innovations allow users to easily produce full-color transfers, enhancing the overall crafting experience.

| Aspect | DTF Transfers | Sublimation Printing | Screen Printing |

|---|---|---|---|

| Fabric Compatibility | Versatile (cotton, polyester, blends) | Limited to polyester | Good for cotton and blends but requires multiple screens for multicolor designs |

| Setup Complexity | Simple heat press application | Complex heat infusion process | Higher setup costs, especially for multicolor |

| Cost-Effectiveness | Cost-effective for small runs, no need for multiple screens | Cost-effective in bulk; higher initial costs | Affordable in large quantities; high initial setup cost |

| Print Quality | High-quality, vibrant, durable prints | Excellent color quality; traditional method | Good quality but may fade over time with certain setups |

| Recent Developments | Innovations provide quick turnarounds and simplicity | Stable but limited by materials | Effective for large businesses but slower for small orders |

Summary

DTF Transfers stand out as a transformative printing method in the custom apparel landscape, combining versatility, cost-effectiveness, and high-quality results. As businesses and hobbyists navigate their printing choices, understanding the distinctions between DTF transfers and traditional techniques like sublimation and screen printing is vital. This enables an informed decision that aligns with project needs, ensuring optimal outcomes for custom designs. Embracing the advancements in DTF technology allows for innovative solutions, thereby enhancing creativity and efficiency in fabric printing.