DTF transfers, short for Direct-to-Film transfers, are making waves in the custom apparel printing industry, transforming how designs are applied to fabric. This innovative technology allows for vivid, detailed prints that are not only eye-catching but also remarkably durable, setting a new standard for high-quality garment decoration. By utilizing DTF technology, businesses can explore a world of customization that was previously hard to achieve with traditional printing methods. With the rise of services like Sam’s DTF Transfers and Insta DTF, entrepreneurs now have access to efficient solutions that can enhance their offerings. As this printing method gains momentum, understanding DTF transfers becomes essential for anyone looking to excel in the custom apparel market.

The realm of fabric decoration has evolved significantly with the introduction of Direct-to-Film methods, often referred to simply as DTF technology. This modern approach to custom apparel printing encompasses a wide array of practices, allowing for intricate designs that adhere seamlessly to various textiles. As the demand for personalized clothing increases, decorators are turning to these innovative solutions to deliver vibrant prints that withstand the test of time. Terminologies such as flexible printing and high-resolution textile applications encapsulate the advancements achieved through DTF transfers, making them an appealing choice for designers and businesses alike. By leveraging these state-of-the-art techniques, entrepreneurs can elevate their brand offerings while meeting customer demands with efficiency.

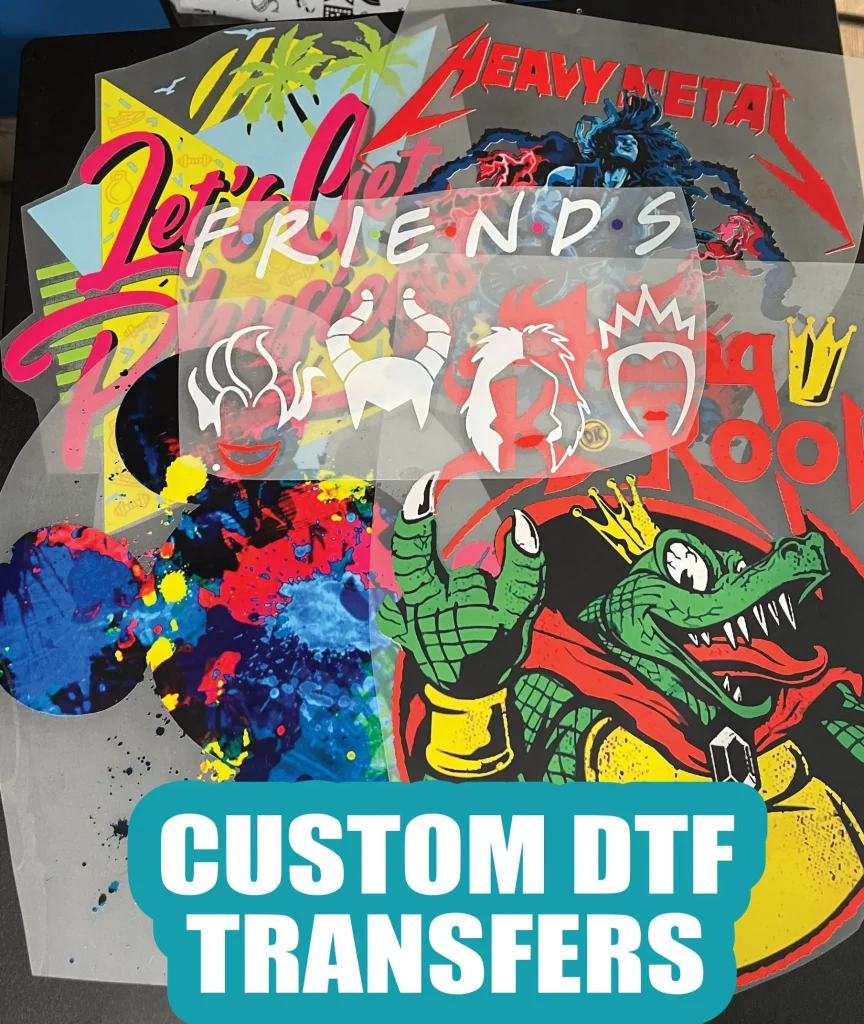

Understanding the Basics of DTF Transfers

Direct-to-Film (DTF) transfers are a cutting-edge printing technique that allows designers and apparel makers to create intricate designs on a special film. This film is then transferred onto fabric using heat, which yields stunning, vibrant prints. Unlike traditional screen printing methods, DTF technology is incredibly versatile, making it suitable for a wide range of materials, including cotton, polyester, and blends. The process not only enhances the vibrancy of colors but also preserves the intricacy of designs, enabling small businesses to fulfill customer requests for bespoke items without compromising on quality.

DTF transfers are particularly advantageous for custom apparel printing as they afford businesses the flexibility to produce small runs of unique designs at a lower cost compared to conventional printing techniques. For entrepreneurs looking to make their mark, understanding these basics can lead to significant opportunities in growing their brand presence and customer loyalty. By utilizing DTF transfers, businesses can capitalize on niche markets and cater to evolving fashion trends, ensuring that they stay ahead in a competitive industry.

The Advantages of DTF Technology for Apparel Printing

The adoption of DTF technology in the custom apparel sector has highlighted numerous advantages that make it a preferred choice for many decorators. One of the primary benefits is the level of durability that DTF prints exhibit. These transfers are designed to withstand rigorous washing and wearing, ensuring that the vibrancy of colors remains intact over time. This quality is particularly beneficial for brands aiming to create long-lasting relationships with their customers by delivering products that maintain their aesthetic appeal even after multiple washes.

Furthermore, DTF transfers allow for a seamless printing experience, enabling businesses to create complex designs with ease. The technology supports rich color saturation and fine details that traditional methods often struggle to provide. As customer demand for personalized and eye-catching apparel increases, the capability to produce high-quality DTF prints quickly can help businesses meet those expectations, ultimately contributing to customer satisfaction and repeat business.

Innovations Driving the DTF Transfer Market

The DTF transfer market is constantly evolving, driven by innovative advancements that enhance production processes and product quality. Companies such as Insta Graphic Systems are at the forefront with solutions like their Insta DTF heat transfer, which boasts greater durability and vibrancy. These innovations not only improve the visual appeal of the prints but also optimize operational efficiencies, allowing businesses to produce more in less time. The ongoing development in DTF technology is paving the way for unprecedented possibilities in apparel customization.

Additionally, as industry leaders like Sam’s DTF Transfers invest in research and development, the effectiveness of DTF technology continues to grow. Such advancements foster a competitive edge for those engaged in the custom apparel market, enabling them to offer superior products that meet contemporary consumer demands. By staying informed about these innovations, businesses can leverage new tools and resources that amplify their capabilities and enhance their market position.

Effective Practices for Implementing DTF Transfers

To successfully integrate DTF transfers into a custom apparel business, adhering to effective practices is crucial. Investing in top-quality printers and supplies is the first step. Businesses must seek out reputable brands renowned for their DTF printing equipment that promises reliability and exceptional print quality. The right machinery not only minimizes downtime but also supports consistent production quality, which is vital for maintaining customer trust.

Equally important is ensuring that staff members are adequately trained in the DTF printing process. This includes understanding machine operations, artwork preparation, and material handling. Regular training sessions can help streamline operations and reduce errors, ultimately contributing to an efficient workflow. Furthermore, staying attuned to industry trends should be part of the strategy, as it enables businesses to adapt to changing demands and embrace new technologies as they arise.

Maximizing Customization with DTF Transfers

One of the standout features of DTF transfers is their inherent ability to facilitate extensive customization. As consumer preferences shift towards personalized products, DTF technology allows businesses to cater to these needs efficiently. Creating custom designs for individual customers or specific niche markets can significantly enhance brand loyalty and consumer engagement. By leveraging DTF transfers, businesses can produce everything from unique t-shirts to customized merch, catering to diverse audiences.

In practice, this means that businesses equipped with DTF technology can respond rapidly to trends, seasonal demands, or special events like holidays and tournaments. The ability to swiftly turn around custom orders without the drawbacks associated with traditional printing methods not only boosts profitability but also positions companies as leaders in customer satisfaction. Engaging with customers on a personal level through directly customized products can lead to increased sales and a stronger brand identity within the marketplace.

Navigating Trends in DTF Transfers for Future Growth

As the landscape of custom apparel continues to transform, staying ahead of trends related to DTF transfers is essential for sustained growth. This includes being aware of color palette preferences, design styles, and even fabric choices consumers gravitate towards. By closely monitoring these trends, businesses can adapt their offerings to align with what is currently appealing in the market, ensuring they remain competitive and relevant.

Moreover, leveraging digital platforms for marketing DTF printed apparel has proved effective. Social media channels provide a potent avenue for showcasing custom designs and engaging with potential customers. By utilizing innovative approaches to promote DTF transfers, businesses can widen their reach and establish a robust online presence that resonates with their target audience. Ultimately, a forward-thinking mindset will enable companies to harness the full potential of DTF technology while paving the way for long-term success.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing a design onto a specialized film that is then heat-pressed onto fabric. This method allows for vibrant and durable prints, making it ideal for custom apparel printing.

What advantages do DTF technology offer for custom apparel printing?

DTF technology offers several advantages, including high vibrancy, enhanced durability, flexibility with various fabrics, and cost-effectiveness for small runs. These benefits make DTF transfers a popular choice for customizing apparel.

Can I use DTF transfers on any type of fabric?

Yes, DTF transfers can be applied to a variety of fabrics, including cotton, polyester, and blends. This versatility allows businesses to cater to different garment types and customer preferences.

How does Insta DTF improve the DTF printing process?

Insta DTF, developed by Insta Graphic Systems, enhances the ornamentation quality of prints, providing improved vibrancy and durability. This innovation streamlines the printing process, reducing turnaround times and improving efficiency for businesses.

What should I consider when starting with DTF transfers for my business?

When starting with DTF transfers, invest in quality equipment, source high-quality films and inks, and ensure effective staff training. Staying updated on trends and innovations in DTF technology is also crucial for continued success.

How can Sam’s DTF Transfers assist small businesses in custom apparel printing?

Sam’s DTF Transfers supports small businesses by offering quality DTF transfer services and providing resources, advice, and a commitment to craftsmanship. This approach fosters a creative environment conducive to growth and innovation in custom apparel.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | Direct-to-Film (DTF) transfers involve printing designs onto a film that is then heat-pressed onto fabric, offering vibrancy, durability, flexibility, and cost-effectiveness. |

| Key Developments in Technology | 1. Emergence of leaders like Sam’s DTF Transfers. 2. Innovations like Insta Graphic Systems’ Insta DTF solution. 3. Support for entrepreneurs in the DTF market. |

| Benefits of Using DTF Transfers | 1. Customization at scale. 2. Expanded reach to niche markets. 3. More sustainable printing options. |

| Best Practices for Implementation | 1. Invest in quality equipment. 2. Source high-quality films and inks. 3. Train staff effectively. 4. Stay updated on trends and innovations. |

Summary

DTF transfers have become a game-changer in the custom apparel industry, allowing businesses to capitalize on vibrant, high-quality prints with numerous advantages. This innovative technique not only enhances design quality but also supports small business growth through improved customization and sustainability. As more companies embrace DTF technology, it’s clear that DTF transfers are essential for staying competitive in a rapidly evolving market. By following the best practices and leveraging the latest advancements, businesses can unlock their full potential and meet the demands of their customers effectively.