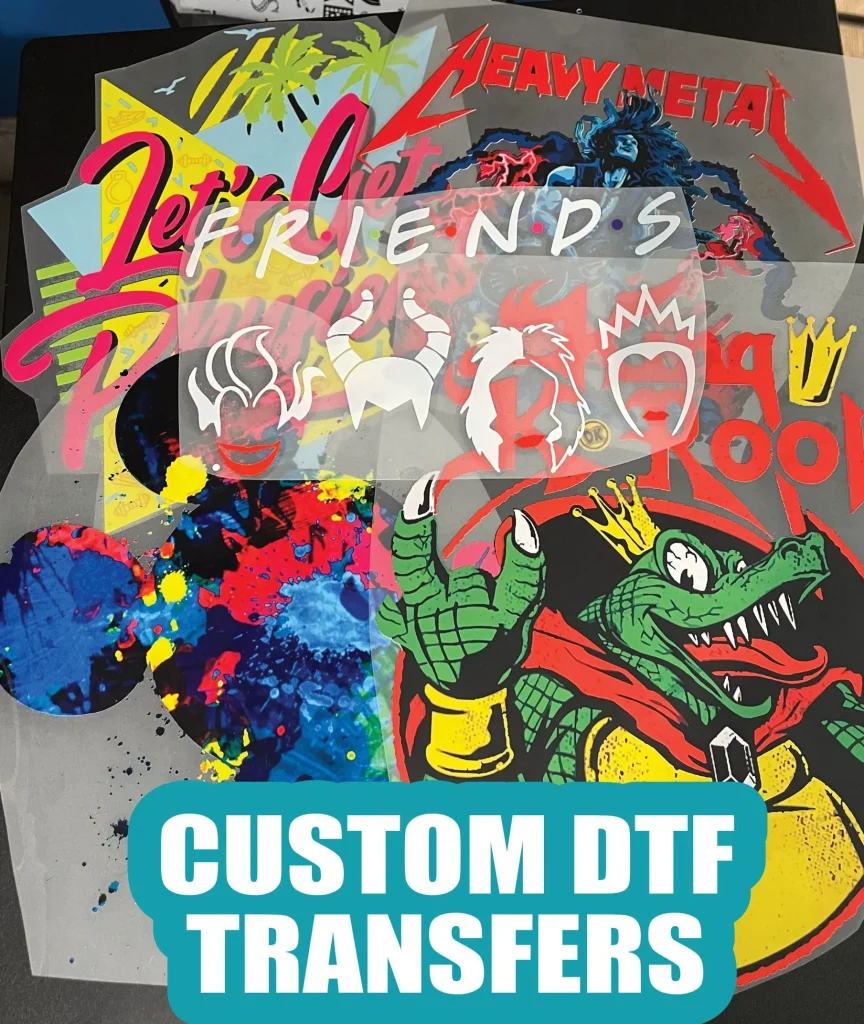

In the ever-expanding realm of custom apparel, DTF transfers stand out as a cutting-edge technique poised to transform the textile printing industry. Direct-to-Film printing harnesses advanced technology to effortlessly transfer bright, detailed designs onto a wide array of fabrics, enabling creators to craft personalized clothing that captivates customers. As businesses and hobbyists alike explore the versatility of DTF printing technology, its ease of use and quick turnaround times have made it a preferred choice for custom apparel production. Additionally, DTF transfers embody the shift towards sustainable textile printing, incorporating eco-friendly inks and materials into the production process. In this guide, we will explore the DTF transfer process, its benefits, best practices, and the latest innovations lighting the way for future printing endeavors.

DTF transfers, also known as Direct-to-Film transfers, are revolutionizing how we personalize and print on fabrics. This innovative approach to printing allows for high-resolution images to be printed on specialized film before being applied to textiles, resulting in stunning apparel that’s both durable and vibrant. The flexibility offered by this method caters to a wide range of materials, making it an ideal solution for designers looking to create unique pieces. As we explore the nuances of the DTF transfer technique, we will look into its advantages, the sustainability aspect of this printing method, and how it aligns with the growing trend of eco-conscious manufacturing in the apparel industry.

Understanding DTF Transfers: A Revolutionary Printing Method

Direct-to-Film (DTF) transfers represent a leap forward in custom apparel technology, offering a seamless solution for creating vibrant, detailed prints on a variety of fabrics. DTF printing involves printing your artwork onto a special film layer that can adhere to textiles of all kinds, including cotton and polyester. This method eliminates the need for screen printing setup, significantly reducing the time and resources typically required. Today, DTF has become a favored choice not only for small businesses but also for hobbyists who wish to bring their design ideas to life without a hefty investment.

The innovative DTF transfer process is user-friendly; it allows users to easily pre-press their fabric, print designs using specially formulated inks, and apply them using heat and pressure techniques. This straightforward approach has significantly democratized the textile printing industry, allowing even newcomers to produce professional-grade apparel from the comfort of their home or workshop. The strong adhesion and vibrant colors achievable with DTF also make it suitable for various markets, ranging from fashion to promotional items.

Recent Advancements in DTF Printing Technology

The DTF printing realm has witnessed impressive technological advancements that have simplified and enhanced the printing process. Newer models of DTF printers are equipped with state-of-the-art features such as integrated software for design enhancements and automatic color matching, which contribute to an overall improved user experience and print quality. This innovation ensures that artists and businesses can keep pace with their creative visions without compromising on efficiency.

Furthermore, the quality of DTF transfer films has seen great improvements as manufacturers strive to offer more durable options. Enhanced film types ensure better ink adhesion and longevity, meaning that the final products are not only visually appealing but also withstand the test of time in terms of washes and wear. As technology continues to evolve, the possibilities associated with DTF printing are expanding, welcoming an array of exciting applications in custom apparel, merchandise, and more.

The Growing Market for DTF Transfers

As the custom apparel industry continues to grow, the demand for DTF transfers is also on the rise. DTF technology offers unparalleled versatility allowing users to print on a variety of materials beyond textiles, such as bags and hats. This broad applicability is a defining factor that is making DTF a mainstream option in both small and large-scale manufacturing processes. The ability to create low-volume custom designs economically appeals to boutique businesses looking to differentiate their products.

According to market research, the surge in demand for personalized and on-demand printing solutions has correlated with the increasing popularity of DTF technology. This trend supports entrepreneurs in launching their unique fashion lines quickly and cost-effectively. As awareness of DTF transfers spreads, more businesses are integrating this advanced printing method into their operations to capitalize on consumer preferences for custom designs.

Sustainability in DTF Printing

The DTF printing process is also stepping into a more sustainable future, with significant efforts seen within the industry to adopt eco-friendly practices. Many manufacturers are increasingly focusing on using water-based inks, which lessen the environmental impact compared to traditional solvent-based inks often utilized in other printing methods. This shift is crucial for businesses aiming to market their products to environmentally conscious consumers, enhancing the overall appeal of DTF printed items.

Moreover, advancements in DTF transfer technology contribute to sustainable printing efforts by optimizing material usage. Improved printer efficiencies reduce waste and ultimately, the carbon footprint associated with manufacturing custom apparel. As more brands commit to sustainability, DTF printing positions itself as a viable solution for forward-thinking businesses wanting to appeal to a demographic that values green practices.

Best Practices for Successful DTF Transfers

To achieve optimal results with DTF transfers, adhering to best practices is key. First and foremost, investing in high-quality DTF printers and transfer films ensures that the end results meet professional standards. It’s equally essential to understand the nuances of different fabric types; each material may require specific printing techniques to achieve the best adhesion and color vibrancy.

Additionally, ensuring accurate heat application and press duration is critical to the transfer process. Missteps here can lead to poor quality prints that can peel or fade over time. Businesses and individuals engaged in DTF printing should utilize readily available online resources, including video tutorials and step-by-step guides, to continually refine their processes and improve output quality.

Cost Considerations for DTF Printing Setup

When considering a shift to DTF printing, understanding the costs associated with setting up your equipment is vital. The initial investment can vary widely based on the quality of the printer and the accessories required, such as heat presses and inks. However, DTF printing often proves more economical in the long run, as businesses can scale production efficiently without the overhead costs associated with traditional printing methods.

As operators become familiar with the process, they often find savings through reduced material waste and increased production speeds. Many have reported that the return on investment for DTF printing can be realized relatively quickly, particularly for businesses focused on custom apparel production. By effectively managing costs, businesses can continue to thrive while delivering high-quality, personalized products to their customers.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve a unique printing process where designs are printed onto special film. This film is then applied to fabrics using heat and pressure, enabling vibrant, full-color prints on various materials.

What advantages does DTF printing technology offer for custom apparel?

DTF printing technology offers numerous advantages for custom apparel production, including the capability to print on a wide range of fabrics, high-quality color reproduction, and a user-friendly process that makes it accessible for both beginners and professionals.

Are DTF transfers a sustainable option for textile printing?

Yes, DTF transfers can be a sustainable choice. The industry is shifting towards eco-friendly inks and optimizing printing processes to reduce waste, making DTF printing a thoughtful option for businesses that prioritize sustainability in their operations.

What are the best practices for successful DTF transfer printing?

To ensure successful DTF transfer printing, select high-quality DTF printers and films, adjust heat settings appropriately for different fabrics, and follow manufacturer guidelines. Engaging with online resources can also provide valuable tips and support.

How can I get started with DTF transfers for my custom apparel business?

To get started with DTF transfers, research and choose suitable DTF printers and films, gather essential supplies like DTF ink and heat presses, create your designs using graphic software, and practice the transfer process to refine your results.

What are the cost implications of investing in DTF printing technology?

Investing in DTF printing technology can vary in cost, but benefits like reduced material waste and increased production efficiency often lead to returns on investment over time, particularly for businesses scaling up their custom apparel production.

| Key Points | Details |

|---|---|

| What Are DTF Transfers? | DTF printing involves printing designs on a special film, then applying them to fabric using heat and pressure. |

| Recent Developments | Technology advancements, market growth, user-friendly processes, sustainability efforts, best practices, and cost implications. |

| Technology Advancements | User-friendly integrated software has improved DTF printing efficiency for both home and industrial use. |

| Market Growth | The flexibility to print on various materials has attracted many small businesses to DTF printing. |

| User-Friendly Processes | Availability of comprehensive tutorials and guides makes DTF printing accessible to novices. |

| Sustainability Considerations | The industry is moving towards eco-friendly inks and materials to reduce environmental impact. |

| Best Practices | Selecting quality equipment and adjusting settings based on fabric types are crucial for success. |

| Cost and Investment | Investing in DTF printing can be cost-effective over time as efficiency improves. |

| How to Get Started | Research equipment, gather supplies, create designs, print and transfer, test, and market your creations. |

Summary

DTF transfers have emerged as a transformative method in the realm of custom apparel, combining innovation with accessibility. This technique not only elevates printing quality but also accommodates varied fabric types, making it an ideal choice for both small businesses and hobbyists. The rise of DTF transfers highlights a significant shift towards sustainable practices in textile printing, reflecting growing consumer demand for environmentally friendly solutions. As more creators and entrepreneurs explore DTF opportunities, the potential for artistic expression and market expansion continues to grow.