DTF transfers, or Direct To Film transfers, are transforming the landscape of fabric printing by giving artists and designers an innovative solution to create eye-catching and long-lasting designs. This cutting-edge technology facilitates the printing of vibrant fabric designs that not only appeal to the eyes but also promise exceptional durability, making them an outstanding choice for custom apparel. With eco-friendly inks for DTF continuing to gain traction, businesses can now adopt sustainable practices while maintaining high-quality output. As we delve into the world of DTF transfer technology, you will discover the versatility of this printing method that allows for intricate details and brilliant colors on a variety of materials. Whether you are a hobbyist or a seasoned professional, understanding DTF transfers will undoubtedly enhance your design capabilities and market appeal.

Direct to Film (DTF) printing has emerged as a revolutionary technique within the custom fabric industry, renowned for its ability to produce striking and resilient prints. This innovative method combines art and technology, allowing designers to achieve intricate details and rich coloration on fabrics ranging from cotton to polyester blends. The durability of DTF prints is a game-changer for apparel, as it withstands repeated washes while retaining vibrancy and visual impact. By using eco-conscious inks, this process not only meets consumer demand for quality but also aligns with environmental sustainability initiatives. In exploring this modern printing solution, designers can enhance their offerings and embrace a future filled with creativity and responsibility.

Exploring the World of DTF Transfers

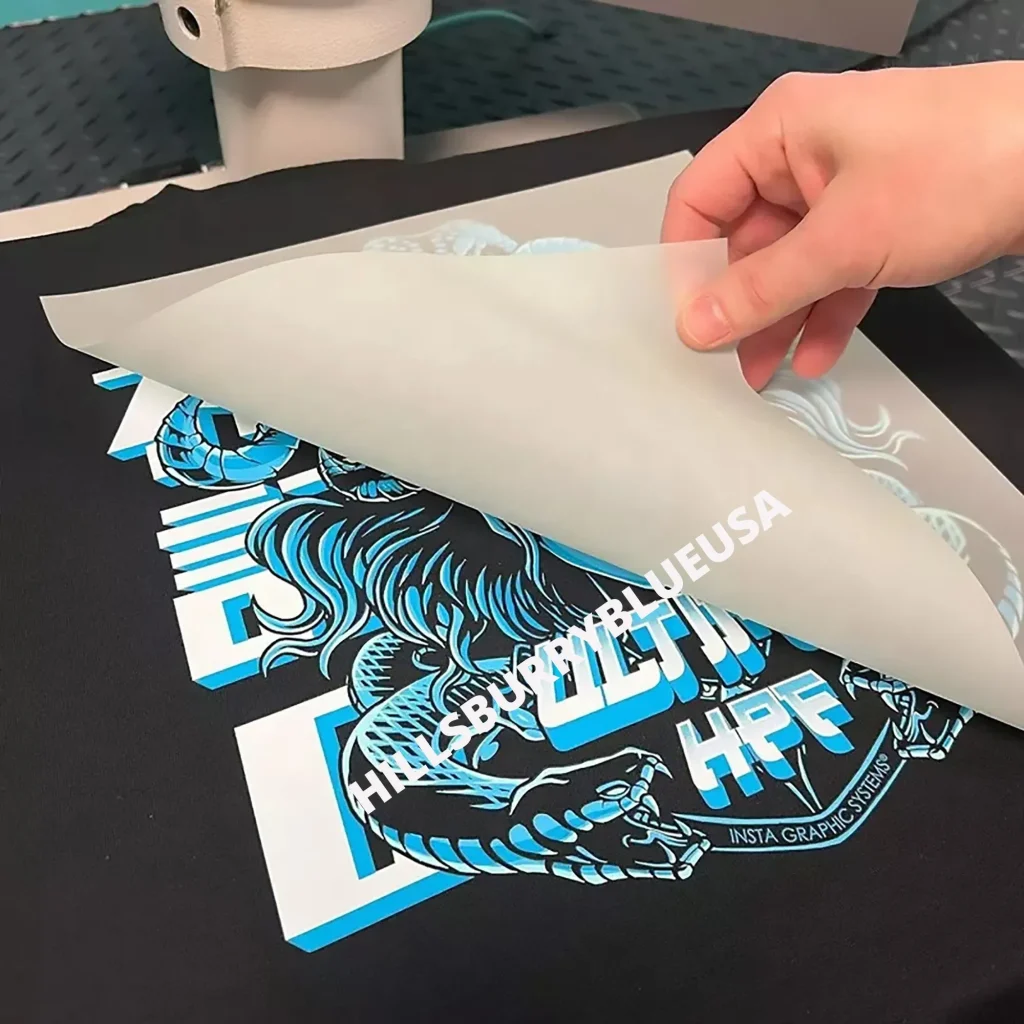

DTF transfers, or Direct to Film transfers, represent a groundbreaking technology in the realm of textile printing. This innovative method enables designers to transfer intricate designs directly onto fabric, ensuring a high level of detail and vibrancy. By utilizing specialized films and advanced adhesive techniques, DTF transfers allow for the creation of vivid and durable graphics that can be applied to a plethora of surfaces. This versatility is what makes them so appealing to a variety of users—from hobbyists creating custom shirts to large-scale businesses producing branded merchandise.

The appeal of DTF transfer technology lies not only in its multifaceted application but also in its ease of use and quality output. Designers appreciate the straightforward process that allows them to achieve professional-level results without needing extensive training. As more businesses recognize the benefits of DTF printing, the demand for this method is projected to grow, resulting in even more advancements in technology and materials used, cementing DTF transfers as a mainstay in the fabric printing industry.

Durability: The Key Advantage of DTF Transfers

One of the most compelling reasons to choose DTF transfers over other printing methods is their remarkable durability. Designed to withstand the rigors of regular wear, DTF prints maintain their quality even after numerous washes. This durability is attributed to the advanced adhesives used in the process, which form a robust bond between the ink and fabric. As a result, garments featuring DTF prints resist common issues such as fading, cracking, and peeling, making them an ideal choice for uniforms and casual wear alike.

Maintaining high-quality DTF transfers also requires understanding the printing environment and proper manufacturing practices. The selection of materials, including fabric type and ink quality, can significantly influence the longevity of the prints. Ensuring that the fabric is prepped correctly and utilizing proper heat application during the transfer process are crucial for maximizing durability. By adhering to these best practices, designers can produce garments that not only look great but are also built to last.

Vibrant Designs: The Artistic Edge of DTF Transfers

Vibrancy is another standout feature of DTF transfers, allowing for the creation of artwork that captivates and engages. The technology used in DTF printing enables artists to produce a wide range of colors and intricate designs that stand out on fabric. The broad color gamut ensures that every shade is accurately represented, leading to the creation of stunning visuals that pop against the material. This is particularly beneficial for custom apparel where a striking design can make all the difference.

The secret behind the vibrancy of DTF transfers lies in the special inks used during the printing process. These inks are designed not only to deliver rich color saturation but also to adhere well to textiles, enhancing both the appearance and the tactile quality of the prints. Additionally, improved formulations that focus on eco-friendly properties mean that designers can now produce vibrant and appealing items while also committing to sustainable practices in their production methods.

DTF Transfer Technology: Innovations and Future Directions

As the fabric printing industry advances, DTF transfer technology continues to push boundaries with innovative solutions. In recent years, the introduction of eco-friendly inks has revolutionized the market, allowing designers to create sustainable prints without sacrificing quality. These inks meet environmental standards and offer excellent performance, enabling businesses to appeal to the growing demographic of eco-conscious consumers.

Moreover, the accessibility of DTF printing equipment has expanded significantly. With affordable options now available, small businesses and individual creators can easily enter the market, driving further innovation and competition within the industry. As technology progresses, we can expect even more enhancements in the speed, efficiency, and quality of DTF transfers, securing their place as a go-to solution for many designers.

Best Practices for Effective DTF Transfer Application

To achieve the best results with DTF transfers, applying best practices during the transfer process is paramount. Start by properly preparing the fabric; rinsing and drying it beforehand can make a significant difference in adhesion and overall print quality. By removing any residues, you ensure that the DTF transfer adheres optimally, leading to longer-lasting and more vibrant designs.

Moreover, accuracy in application is crucial. Setting the right temperature and pressure levels when heat pressing the transfer directly influences its quality. Following manufacturer guidelines will help ensure that the printed design retains its vibrancy and durability over time. Providing customers with care instructions—such as washing in cold water and avoiding direct ironing on the print—will further extend the life of DTF-printed garments, ensuring satisfaction and repeat business.

Conclusion: Embracing the Future of DTF Printing

In conclusion, DTF transfers represent a remarkable evolution in the field of fabric printing, offering a unique blend of durability and vibrancy. As technology continues to advance, designers and businesses have access to tools that not only enhance their creative potential but also align with sustainability goals. Understanding the nuances of DTF printing can significantly benefit designers, allowing them to produce high-quality, lasting products that speak to their audience.

As we move forward in the ever-evolving landscape of textile printing, embracing DTF technology will be essential for anyone looking to stay competitive. The potential for impressive designs that withstand the test of time is unparalleled, making DTF transfers an invaluable asset in the toolkit of modern designers. The future of DTF printing is bright, and the possibilities for creativity are endless.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct To Film transfers, are a printing technique where designs are printed onto a special film. This film is then heat-pressed onto fabric, allowing for vibrant fabric designs. The process enables detailed, colorful graphics to be transferred onto various materials, making it popular among custom apparel designers.

How durable are DTF transfers compared to other printing methods?

DTF transfers are known for their durability, often lasting over 50 washes without losing vibrancy or quality. This durability stems from advanced adhesive technologies, ensuring that the ink adheres strongly to the fabric. Compared to other printing methods, DTF transfers resist cracking and peeling, making them ideal for high-wear garments.

What advantages do DTF transfers offer in terms of color vibrancy?

The DTF transfer technology uses high-quality inks that provide a wide color gamut, resulting in vibrant fabric designs. The unique transfer process helps lock pigments onto the fabric, enhancing color saturation and brilliance, making DTF prints stand out compared to other printing methods.

Are there eco-friendly options for DTF transfers?

Yes, recent developments in DTF technology include eco-friendly inks, which provide excellent performance while minimizing environmental impact. These inks are made to comply with sustainable practices, offering businesses the option to produce high-quality DTF transfers without compromising on ecological responsibility.

What are the best practices for applying DTF transfers?

To ensure effective DTF transfers, it’s crucial to prepare the fabric properly by washing it beforehand, apply the correct heat and pressure settings, and provide customers with maintenance guidelines. Following these best practices helps to enhance the durability and vibrancy of the DTF prints.

What recent advancements are there in DTF transfer technology?

Recent advancements in DTF transfer technology include the development of eco-friendly inks and more affordable printing equipment. These innovations make DTF printing accessible to small businesses and hobbyists, promoting the widespread adoption of this versatile and vibrant printing method.

| Key Point | Details |

|---|---|

| Introduction to DTF Transfers | DTF transfers are a printing method that allows for vibrant, durable designs on fabric. |

| What is DTF Transfer? | A technique where designs are printed on a special film and then transferred onto fabrics using heat and pressure. |

| Durability of DTF Transfers | Can withstand over 50 washes without losing quality; resist cracking, fading, and peeling. |

| Vibrancy of DTF Transfers | Utilizes high-quality inks that provide a wide color gamut and brilliant designs. |

| Recent Developments in DTF Technology | Advancements include eco-friendly inks and affordable printing equipment for wider access. |

| Best Practices for DTF Transfers | Includes proper fabric preparation, accurate application settings, and maintenance guidelines. |

Summary

DTF transfers represent a groundbreaking technique in the realm of fabric printing, solidifying their niche due to unmatched durability and vibrancy. As designers seek methods to achieve stunning visuals without compromising quality, DTF transfers emerge as the go-to option. This revolutionary printing technology is not only friendly to the environment but also economically accessible, making it ideal for both hobbyists and professional designers alike. As the industry continues to innovate, the versatility and efficiency of DTF transfers will surely lead to even more dynamic applications in fashion and custom apparel, ensuring that creativity can flourish while maintaining an eco-conscious approach.