DTF transfers, or Direct-to-Film transfers, are revolutionizing the printing industry by offering a superior method for applying intricate designs onto various fabrics. This innovative technique leverages state-of-the-art printing technology, providing businesses with high-quality, vibrant prints that stand out in a crowded market. Unlike traditional methods such as sublimation printing and screen printing, DTF transfers offer versatility across different textiles, including cotton and blends, making them an excellent choice for diverse applications. Additionally, this eco-friendly printing approach minimizes waste, appealing to environmentally-conscious consumers while ensuring durability and longevity of the printed designs. In this article, we will explore the benefits of DTF transfers compared to other popular printing methods to help you decide which one is best for your business.

Direct-to-Film printing, also known as custom transfer printing, is increasingly gaining popularity among businesses seeking efficient and high-quality solutions for fabric decoration. As a noteworthy alternative to more traditional techniques like screen printing, vinyl printing, and sublimation, DTF technology offers unique advantages that cater to a wide array of printing needs. This method allows for seamless application of detailed graphics onto various materials, opening up opportunities for crafters and enterprises alike. Moreover, the emphasis on eco-friendly practices and reducing waste aligns with the growing demand for sustainable printing methods. In this exploration, we will delve deeper into the distinctions and advantages of DTF printing within the context of the broader printing landscape.

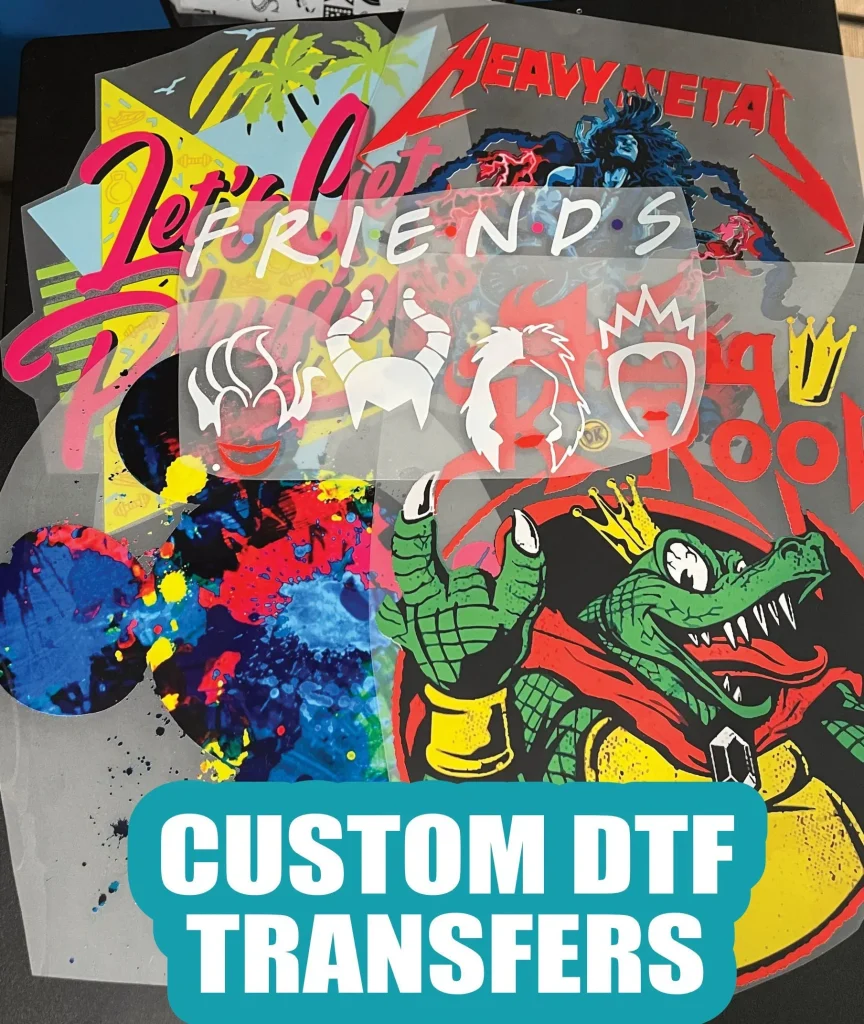

The Process of DTF Transfers Explained

DTF transfers, or Direct-to-Film transfers, utilize a unique printing process that involves creating high-quality prints on a special film before applying them to the garment. This method starts with the design being printed onto a DTF film using advanced printers equipped with vibrant inks. Once printed, the design is covered with an adhesive powder, which is then melted and cured using heat, encapsulating the design in a durable layer. After cooling, the film can be applied to various textiles using a heat press, resulting in sharp, vivid prints that adhere well to different fabric types.

One significant advantage of DTF printing is its versatility in material compatibility. Unlike sublimation printing, which works effectively only on polyester or specially coated fabrics, DTF can be used on a wide array of materials, including cotton, nylon, and blends. This opens avenues for businesses to diversify their offerings, catering to broader customer needs. Though compared with screen printing, DTF is simpler and often faster, making it an attractive option for startups and small businesses looking to enter the market quickly.

Eco-Friendly Characteristics of DTF Transfers

As businesses increasingly prioritize sustainability, DTF printing stands out with its eco-friendly characteristics. Unlike traditional printing methods that often generate significant waste, DTF technology is designed to optimize ink usage and minimize fabric off-cuts. Its precise application ensures that only the necessary materials are utilized, which can significantly reduce the environmental impact of textile production. This makes DTF printing not only a cost-effective choice but also an appealing option for companies eager to enhance their green credentials.

Moreover, DTF’s commitment to sustainability extends beyond just material savings. Many printers use water-based inks that are less harmful to the environment, making this method an attractive choice for eco-conscious consumers. By choosing DTF transfers, businesses can effectively communicate their dedication to environmentally friendly practices, thereby attracting customers who prioritize sustainability in their purchasing decisions. This alignment with consumer values presents a competitive advantage in the increasingly eco-aware market.

Comparing Benefits: DTF Transfers vs. Sublimation

When comparing DTF transfers with sublimation printing, several factors come into play. Sublimation is renowned for its vibrant colors and smooth finish since the dye is infused directly into the fabric fibers. However, this method is limited primarily to polyester and polymer-coated materials. DTF transfers, however, offer a broader range of applications and the ability to print on cotton, blends, and other fabrics, making it a more versatile choice for businesses looking to expand their product offerings.

Additionally, DTF printing provides enhanced durability without compromising quality. Sublimated designs, while striking, may not possess the same level of resilience as DTF transfers, which resist cracking and fading over time. Businesses can benefit from the longevity of DTF prints, ultimately leading to satisfied customers who appreciate high-quality and enduring designs. This aspect positions DTF transfers as a more reliable option, especially for items intended for heavy use, such as workwear and promotional apparel.

Innovative Custom Solutions for DTF Printing

The rise of innovative custom solutions has reshaped the landscape of DTF printing, particularly catering to crafters and small businesses. Services offering custom transfer solutions facilitate easier access to high-quality DTF prints, hastening production times and reducing costs. Many of these platforms are user-friendly, allowing even novices to create unique designs efficiently. As a result, businesses can explore creative possibilities without sacrificing quality or incurring huge overhead costs.

Furthermore, these new platforms provide an extensive library of designs and templates, enabling users to find inspiration and streamline their printing processes. Unlocking access to state-of-the-art DTF technology, businesses can produce eye-catching products that stand out in a competitive market. By utilizing these innovative custom solutions, companies can quickly adapt to changing consumer trends and tailor their offerings to meet specific demands and preferences.

Cost Considerations in DTF Printing

Understanding the cost breakdown involved in DTF printing is crucial for any business considering this method. While the initial investment in equipment may seem daunting, DTF often translates to long-term savings due to its efficiency and reduced material wastage. The use of high-yield inks alongside lower setup costs per print helps businesses manage expenses effectively. Additionally, as DTF technology becomes more mainstream, competition among suppliers often drives prices down, making it an economically feasible option for many.

Moreover, DTF transfers minimize labor costs compared to traditional screen printing methods, which can be labor-intensive and require meticulous setup. With DTF, the learning curve is significantly shorter, allowing new employees to become proficient quickly. This efficiency leads to faster turnaround times and the ability to take on larger volumes of orders without a proportional increase in labor costs, ultimately enhancing a business’s profitability and growth potential.

Evaluating the Versatility of DTF Transfers

Versatility is a standout feature of DTF transfers, setting this method apart from others like screen printing and sublimation. DTF printing allows businesses to seamlessly print on a variety of fabrics, from cotton to blends, making it an ideal choice for diverse product lines including apparel, accessories, and promotional materials. This adaptability supports businesses in responding to customer demands swiftly and effectively, ensuring a strong market presence.

Additionally, the ability to produce multi-colored, detailed designs without the limitations associated with other printing methods positions DTF as a highly flexible solution. Businesses can cater to specialty orders, custom requests, or seasonal trends more readily. This level of versatility encourages creative exploration, enabling brands to innovate and enhance their product offerings while appealing to various customer bases.

Frequently Asked Questions

What are DTF Transfers and how do they compare to sublimation printing?

DTF Transfers, or Direct-to-Film transfers, involve printing designs onto a special film which is then heat transferred onto fabric. Unlike sublimation printing, which is limited to polyester materials, DTF transfers can be applied to a wider range of fabrics, including cotton and blends, offering greater versatility for businesses.

Are DTF Transfers more eco-friendly than traditional screen printing?

Yes, DTF Transfers are generally more eco-friendly compared to traditional screen printing. This method minimizes fabric waste and uses fewer materials, helping to lower the overall carbon footprint associated with garment production, making it a sustainable choice for environmentally-conscious businesses.

How does the quality of DTF Transfers compare to vinyl printing?

DTF Transfers typically provide vibrant colors and excellent detail comparable to vinyl printing. However, DTF prints allow for softer textures on fabrics and are less prone to peeling or cracking, offering a higher quality finish and longevity in comparison to vinyl prints.

Can DTF Transfers be used on all fabric types?

DTF Transfers are versatile and can be used on various fabric types, including cotton, polyester, and blends. This adaptability sets DTF printing apart from methods like sublimation, which works best only on polyester fabrics.

What advantages do DTF Transfers have over traditional heat transfer methods?

DTF Transfers offer several advantages over traditional heat transfer methods, including enhanced durability, the ability to print intricate designs with fine details, and a lower likelihood of peeling or cracking over time, providing businesses with a more reliable printing solution.

How cost-effective is DTF Transfer printing for small businesses?

DTF Transfer printing can be cost-effective for small businesses due to lower operating costs and reduced waste. The initial investment in DTF equipment may be significant, but the long-term savings from efficient material usage and the flexibility of printing on multiple fabric types often outweigh the setup costs.

| Key Point | DTF Transfers | Other Printing Methods |

|---|---|---|

| Sustainability | Minimizes waste and carbon footprint; eco-friendly option. | Traditional methods often produce more waste. |

| Versatility | Can print on cotton, nylon, and more; suitable for diverse applications. | Limited fabric options, particularly with sublimation (only polyester). |

| Print Quality | High-quality, vibrant colors; durable with proper care. | May peel or crack over time, especially with heat transfers. |

| Cost-Effectiveness | Lower long-term costs; efficient use of materials. | Initial setup can be high; ongoing costs may vary significantly. |

| Ease of Use | User-friendly; quicker learning curve for new businesses. | Complex setup and skill required for methods like screen printing. |

Summary

DTF Transfers offer businesses a modern and sustainable approach to printing that caters to a wide array of fabric types while providing high-quality results. As the printing industry continues to evolve, DTF technology enables companies to reduce waste and meet the increasing demand for eco-friendly solutions. With its versatility, durability, and cost-effectiveness, adopting DTF Transfers can position your business strategically in a competitive market. Understanding the distinct advantages of DTF over other methods is critical for maximizing your production capabilities and aligning with contemporary consumer preferences.