In the world of custom apparel decoration, **DTF transfers** are revolutionizing the way designers and businesses create vibrant, eye-catching prints. Utilizing the innovative Direct-to-Film (DTF) printing technology, this method allows for intricate designs to be transferred onto a variety of fabrics with unmatched color accuracy and detail. Many in the garment decoration industry are beginning to recognize the numerous advantages that DTF transfers offer, including their ability to produce stunning graphics without the limitations of traditional screen printing techniques. However, misconceptions abound regarding DTF printing myths, which can hinder its adoption. By understanding the capabilities and benefits of DTF technology, businesses can elevate their custom apparel projects and ensure lasting quality in their designs.

The emergence of Direct-to-Film (DTF) printing marks a significant shift in the realm of custom garment printing and apparel transfers. Often referred to as **film transfers**, this method stands out for its ability to produce finely detailed graphics that adhere seamlessly to various textile materials. As the demand for high-quality garment decoration continues to rise, many are discovering the potential of DTF technology and its advantages over other printing methods. This article will explore the key characteristics of DTF transfers, clear up common misconceptions, and discuss the rising popularity of this innovative technique in the fashion and customization market.

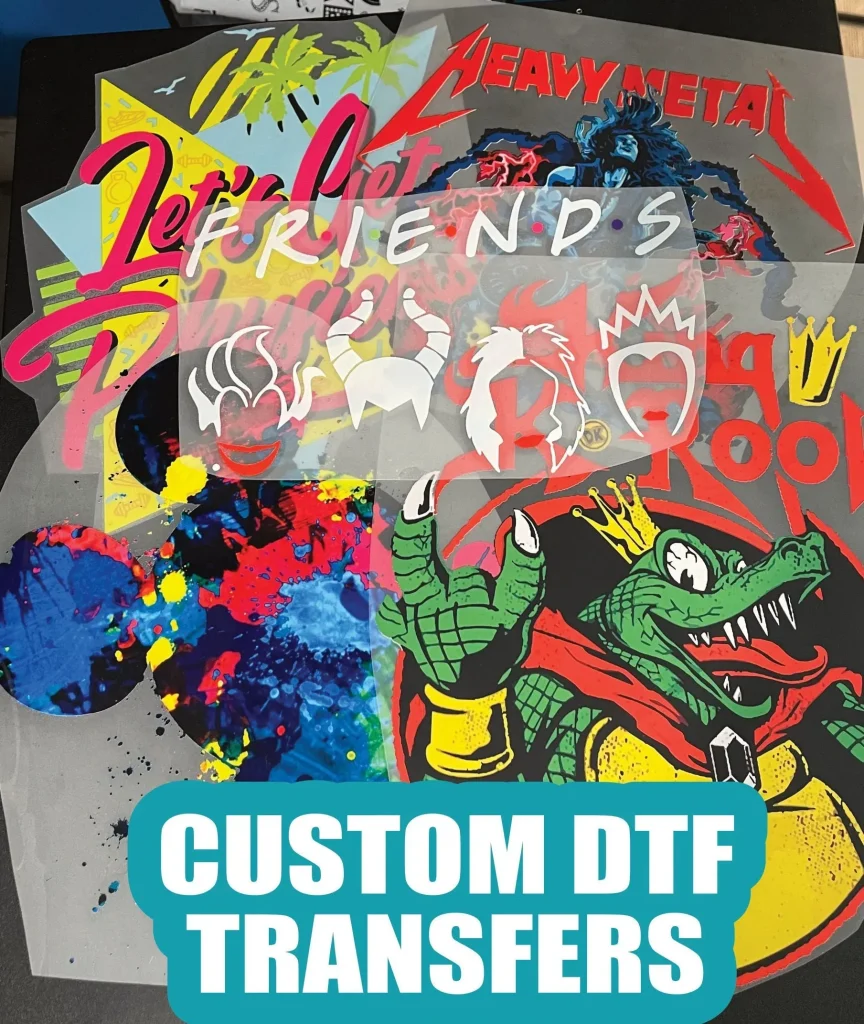

Understanding DTF Transfers in Apparel Decoration

**Direct-to-Film (DTF) transfers** have revolutionized the garment decoration landscape by providing vibrant and detailed prints unlike any traditional method. As industries shift toward bespoke apparel solutions, DTF printing stands out due to its versatility and color accuracy. By initially printing designs onto a special film and utilizing heat to transfer the image onto garments, DTF enables intricate designs that would be difficult or impossible to achieve through other means.

Moreover, DTF transfers cater to a wide range of fabrics, including cotton, polyester, and blends, making them ideal for diverse apparel types. This adaptability is essential for businesses looking to provide customized solutions to their clients. With DTF, even detailed artwork and multi-color prints can be realized with striking brilliance, appealing to customers and enhancing the overall wardrobe.

Dispelling Common DTF Printing Myths

Despite its growing popularity, **DTF printing** is often surrounded by misconceptions. A prevalent myth is that DTF is synonymous with Direct-to-Garment (DTG) printing. In reality, DTF relies on a film transfer technique that stands in stark contrast to the direct ink application of DTG. This difference grants DTF a broader range of compatibility with various materials and often results in vibrant, high-fidelity designs that can outperform DTG in terms of color vibrancy on alternate fabrics.

Moreover, there is a false narrative that DTF transfers do not perform well on dark fabrics. In actuality, advanced DTF technology effectively incorporates white ink into designs, allowing for brilliant color reproduction even against darker backgrounds. This correction in understanding can significantly impact a business’s decision to adopt DTF technology, emphasizing its suitability across multiple fabric types.

The Advantages of Choosing DTF Technology

One of the primary advantages of using **DTF transfers** is the durability they offer. Contrary to the belief that DTF prints are inferior in longevity, when executed with high-quality materials and inks, they can withstand numerous washes without fading or deteriorating. This durability is a significant selling point for businesses looking to compete in a market where longevity of print impacts customer satisfaction.

Furthermore, DTF printing stands out for its cost-effectiveness as an entry point for custom apparel businesses. With lower initial investments required compared to traditional screen printing, smaller shops and entrepreneurs can capitalize on the high-quality outputs provided by DTF technology. This financial accessibility opens doors for many creatives and encourages innovation in garment decoration.

Emerging Trends in DTF Printing

As the custom apparel market expands, so too does the adoption of **DTF technology**. With a growing number of small businesses entering the market, there’s been a noticeable surge in DTF usage, driven by its affordability and high output quality. Trends depict that by 2025, many entry-level businesses will prefer DTF transfers to ensure they provide unique, high-quality products without the hefty costs associated with traditional methods.

Additionally, ongoing advancements in printing techniques and ink formulations enhance the versatility and efficiency of DTF transfers. Improvements such as faster curing times and enhanced adhesive gels leads to quicker turnarounds on print jobs and a wider color palette for designs. These developments are crucial for meeting customer demands for detailed, colorful, and rapid print orders.

Best Practices for DTF Applications

For optimal results in **DTF printing**, applying best practices is key. First and foremost, selecting high-quality films and inks, specifically made for DTF applications, can greatly influence the end product’s quality. These materials ensure that designs are not only vibrant but also durable, standing the test of time against regular wear and washing.

Moreover, keeping your printing equipment updated is essential in the evolving landscape of DTF technology. Outdated printers may produce subpar results and inconsistencies in prints, leading to customer dissatisfaction. Investing in modern equipment ensures that businesses are equipped to harness the full capabilities of DTF and maintain a competitive edge.

The Future of Custom Apparel with DTF Transfers

Looking ahead, **DTF transfers** are set to become a cornerstone of custom apparel decoration. As consumer demands shift towards unique and personalized designs, the capability of DTF to deliver both quality and efficiency positions it favorably in the industry. The current growth statistics indicate that this technology will gain even more traction among businesses seeking to differentiate themselves in a crowded market.

Environmental considerations are also increasingly becoming part of the conversation around DTF printing. Many businesses are now prioritizing eco-friendly practices, and DTF has a potential edge in having a lower environmental impact compared to some traditional methods. This alignment with sustainability goals can further enhance the appeal of DTF technology in the future, attracting environmentally-conscious consumers.

Frequently Asked Questions

What are DTF transfers and how do they work?

Direct-to-Film (DTF) transfers are a printing technique where graphics are printed onto a specialized film, which is then heat-pressed onto the fabric. This method allows for high detail and color accuracy on various fabrics, making it a popular choice for custom apparel decoration.

How do DTF transfers compare to Direct-to-Garment (DTG) printing?

DTF transfers differ from DTG printing as DTF prints on a transfer film before applying to the garment, while DTG prints directly onto fabrics. This process allows DTF to achieve more vivid colors and better versatility across different materials.

Can DTF transfers be used on dark fabrics?

Yes! One of the significant advantages of DTF transfers is their capability to print vibrant colors on dark fabrics by using white ink for base layers. Recent advancements in DTF technology have enhanced this capability, allowing for intricate and colorful designs.

Are DTF transfers durable and long-lasting?

When applied with high-quality inks and films, DTF transfers can be extremely durable, often matching or exceeding the lifespan of traditional screen prints. Proper application and care can ensure they withstand multiple washes without fading or peeling.

What are some advantages of using DTF technology for custom apparel?

DTF technology offers several advantages, including its ability to produce detailed designs on various fabrics, cost-effectiveness for small businesses, and lower environmental impact compared to other printing methods, making it increasingly popular in garment decoration.

What best practices should be followed when using DTF transfers?

To ensure optimal results with DTF transfers, it’s essential to use high-quality films and inks, maintain modern printing equipment, and engage in regular education to stay updated on techniques and advancements in DTF technology.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | A printing technique where graphics are printed on a film and heat-pressed onto fabric, suitable for various materials. |

| Myth 1: DTF = DTG | DTF prints on film before transferring, allowing better material versatility & vivid colors. |

| Myth 2: DTF is not effective on dark fabrics | DTF can print vibrantly on dark fabrics, utilizing white ink for enhanced visibility. |

| Myth 3: DTF prints are not durable | When applied correctly, DTF transfers are as durable as traditional printing methods. |

| Recent Trends | Increasing adoption due to low cost, technological advancements, and environmental considerations. |

| Best Practices | Use quality films/inks, modern equipment, and continue education for optimal results. |

Summary

DTF transfers represent an innovative approach to garment decoration, combining quality and durability for custom apparel printing. By addressing misconceptions and understanding the potential advantages, businesses can effectively utilize DTF transfers to enhance their designs and sustainability practices. This technology is quickly becoming a preferred choice in the apparel industry due to its vibrant results and adaptability. With the right practices in place, DTF transfers not only elevate the quality of designs but also promote environmentally considerate methods in garment production.