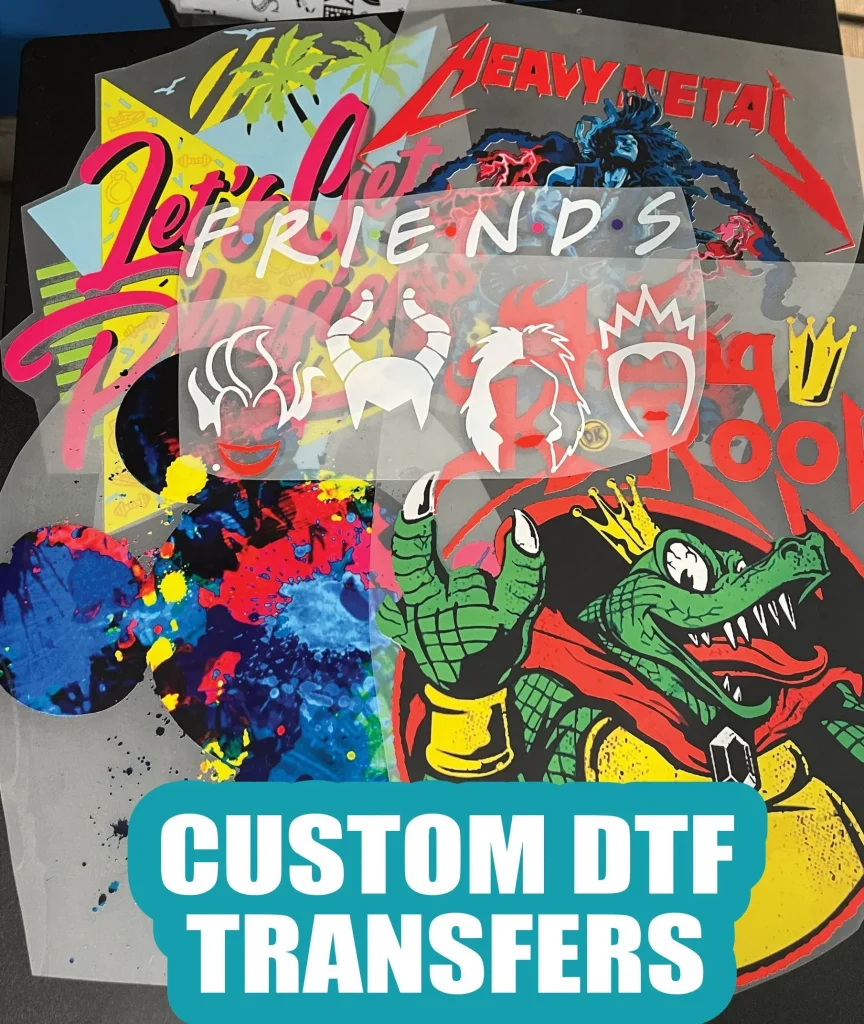

DTF transfers, or Direct-to-Film transfers, are transforming the landscape of printing with their ability to produce striking designs that are both vibrant and resilient on a variety of materials. This innovative DTF printing technology utilizes high-quality PET film for DTF applications, ensuring that every print maintains its clarity and color integrity. The choice of DTF transfer inks is equally crucial, as superior inks enhance the longevity and appearance of the final product. Moreover, to achieve flawless results, investing in a reliable heat press for DTF is essential, providing even pressure and temperature during the transfer process. In this blog, we will explore the best materials for DTF transfers and the advancements that are defining this exciting printing method.

Direct-to-Film transfer technology has emerged as a popular method for achieving high-quality prints on various substrates. This process involves utilizing advanced printing techniques that rely on specialized transfer films, which are printed with vibrant inks. Along with PET films, the inks and adhesives used in this printing method play a significant role in determining the durability and visual appeal of the prints. Additionally, a professional heat press designed specifically for DTF applications is integral to ensuring a successful transfer of the designs onto materials. In the following sections, we will delve deeper into the key materials and technologies that contribute to the success of this innovative printing approach.

Essential Insights into DTF Printing Technology

Understanding Direct-to-Film (DTF) printing technology is critical for anyone looking to excel in the printing business. DTF printing works by applying specially formulated inks onto a transfer film, often made of PET, which is then heat pressed onto the desired substrate. This process provides a unique advantage over traditional screen printing or direct-to-garment methods, allowing for intricate designs and colors to be reproduced with high fidelity. As DTF technology continues to evolve, it is essential to keep an eye on the latest advancements that can enhance print quality and efficiency.

Furthermore, DTF printing technology offers versatility in terms of the materials that can be used. The transfer films can be applied to a wide range of substrates, including textiles, ceramics, and even metal, making this technique one of the most adaptable in the printing industry today. The ability to work with diverse materials means that businesses can cater to a broader audience, thus increasing their market potential. Thus, investing in understanding different aspects of DTF technology helps in harnessing its full capabilities.

Choosing the Best Materials for DTF Transfers

When it comes to DTF transfers, selecting the best materials is crucial for achieving high-quality results. PET film is widely recognized as the best option due to its excellent heat resistance and stability under pressure. This superior material ensures that vibrant colors are transferred accurately and sustainably, resulting in prints that are not only striking but also durable. Additionally, the flexibility of PET film allows for smoother application on various substrates, ensuring that intricate details in designs remain intact.

Quality inks are another vital component in the DTF transfer process, directly influencing the output’s vibrancy and longevity. DTF transfer inks are specially formulated to adhere to the PET film and subsequently bond well with the substrate during the heat transfer process. Investing in high-quality inks not only enhances color accuracy but also improves the overall aesthetic appeal of the final product. It’s essential to consider that employing the right combination of materials is key to ensuring stunning results in every print.

The Role of PET Film in DTF Printing

Polyethylene Terephthalate (PET) film has emerged as the cornerstone of DTF transfers for numerous reasons. Known for its high clarity and smooth surface, PET film allows for exceptional detail in prints. It can withstand high temperatures during the heat pressing process, which is crucial for ensuring that the designs maintain their integrity. The strength of PET film also ensures that prints endure frequent washing, making it an ideal choice for apparel and other items subjected to regular wear and tear.

Moreover, the compatibility of PET film with various DTF transfer inks enhances its utility in the production process. The film’s properties allow for optimal ink adhesion, which not only improves color vibrancy but also ensures a consistent and reliable transfer each time. As a result, the use of PET film significantly reduces the likelihood of fading or cracking, allowing businesses to deliver products that meet customer expectations for quality and longevity.

Importance of Quality DTF Transfer Inks

Choosing the right inks is a vital aspect of achieving optimal results in DTF transfers. High-quality DTF transfer inks, especially those with pigment-based formulations, provide vibrant colors that retain their brilliance even after multiple washes. The formulation of these inks is engineered to enhance adhesion to both the PET film and the substrate, which is essential for long-lasting results. Companies that choose to invest in premium inks often see a significant improvement in the quality and durability of their prints.

Furthermore, the use of white inks in DTF printing cannot be understated. White inks serve a fundamental role in enhancing color brightness when printing on darker substrates. They act as a foundation that allows other colors to pop, giving designers the flexibility to create bold and eye-catching designs. As the DTF printing industry grows, the availability of high-quality inks is expanding, providing more options for creators aiming for exceptional print quality.

Evaluating DTF Adhesives for Maximum Durability

Adhesives are a critical component in the DTF transfer process as they serve to bond the ink and film to the substrate effectively. The quality of the adhesive used can significantly affect the durability and appearance of the final print. High-performance adhesives designed for DTF applications ensure that the prints withstand the rigors of daily use, including washing and exposure to various elements. Selecting the right adhesive enhances the integrity of the prints, making it essential for businesses focusing on quality.

In addition, the compatibility of adhesives with both the PET film and the inks used plays a crucial role in ensuring that the transfer process yields the best results. A great adhesive will not only bond well but also cure effectively under the heat applied during the pressing process, ensuring that the printed designs remain intact. Careful evaluation of different adhesive types can mean the difference between a print that lasts and one that fades after only a few washes.

Selecting the Right Heat Press for DTF Transfers

Choosing the appropriate heat press is essential for achieving successful DTF transfers. Variations in temperature and pressure can greatly impact the transfer quality, leading to poor adhesion and color fading. A heat press that provides consistent temperature and pressure across the entire surface is ideal to maximize the bonding process of the DTF transfer. Investing in a high-quality machine that offers adjustable settings can greatly improve the outcomes of the transfer process.

Moreover, the type of heat press used can also influence the production speed and efficiency. For businesses that aim to scale up their operations, using advanced heat press models that allow for multiple transfers at once can enhance productivity. Additionally, being equipped with digital controls for temperature and time ensures precision in every transfer, allowing you to consistently produce high-quality prints, and ultimately satisfying customer demands for quality merchandise.

Frequently Asked Questions

What are the best materials for DTF transfers?

The best materials for DTF transfers include PET film, quality DTF inks, effective adhesives, and DTF-specific transfer paper. High-quality PET film ensures flexibility and durability, while premium inks provide vibrant colors and longevity. Strong adhesives help maintain product integrity, even after multiple washes.

How does DTF printing technology work?

DTF printing technology utilizes a specialized process where inks are printed onto a PET film that is then heat-pressed onto various substrates. This method allows for high-quality, vibrant prints that adhere well to fabrics and other materials, making DTF a popular choice for custom garment decoration.

What is PET film and why is it important for DTF transfers?

PET film, or Polyethylene Terephthalate film, is essential for DTF transfers due to its flexibility, durability, and heat resistance. It provides a strong base for printing that can withstand high temperatures, ensuring excellent adhesion and color vibrancy during the transfer process.

What types of DTF transfer inks should I use?

For optimal results in DTF transfers, it is important to use high-quality DTF inks that contain strong pigments. These inks offer excellent color reproduction and stability—especially white inks, which enhance the visibility of prints on dark fabrics, ensuring bright and vivid designs.

What role does a heat press play in DTF transfers?

A heat press is critical in the DTF transfer process as it applies the necessary temperature and pressure to adhere the printed design to the substrate. Choosing a reliable heat press that ensures even application is essential for achieving quality and durability in the final print.

How can I improve the quality of my DTF transfers?

To enhance the quality of your DTF transfers, invest in high-quality materials like PET film and DTF inks, experiment with various combinations of adhesives and films, and use a dependable heat press. Staying informed about advancements in DTF printing technology can also significantly impact your results.

| Key Point | Description |

|---|---|

| DTF Transfers | A modern printing method allowing vibrant and durable prints on various substrates. |

| PET Film | The gold standard for transfers due to its flexibility and durability, ensuring excellent color and clarity. |

| Quality Inks | Inks with pigments that provide superior color reproduction and stability, essential for visibility on dark materials. |

| Adhesives | High-quality adhesives bond inks to substrates, ensuring durability and reducing fading. |

| Transfer Paper | Specific types of paper that enhance print quality and adherence of transfers. |

| Heat Press | Crucial for consistent temperature and pressure, affecting adhesion and print quality. |

| Technological Advances | Innovations like Epson’s SureColor G6070 printer that improve DTF printing reliability and accessibility. |

Summary

DTF Transfers are transforming the printing landscape with their ability to produce vibrant, long-lasting designs across various materials. The success of DTF printing heavily relies on the use of high-quality raw materials, including PET film, premium inks, effective adhesives, specialized transfer paper, and reliable heat presses. Recent advancements in DTF technology, like those provided by companies such as Epson and Eazydtf, highlight the growing importance of these components in meeting market demands for superior print quality. By prioritizing these elements, businesses can ensure they create exceptional DTF transfers that stand out in durability and visual appeal.