The DTF printing process, also known as Direct to Film printing, has revolutionized the art of fabric printing, offering unparalleled quality and vibrancy for a myriad of applications. This innovative technique allows for intricate designs and rich colors to be effortlessly transferred onto various textiles, making it an essential tool for businesses in the apparel and promotional sectors. By mastering effective DTF printing techniques and implementing helpful DTF printing tips, you can optimize DTF printing to achieve stunning results that capture attention and stand the test of time. Essential to this process is the selection of high-quality DTF printing materials that enhance the overall durability and appearance of printed products. In this guide, we will explore practical strategies to elevate your DTF printing efforts and ensure your creations exceed client expectations.

Direct to Film printing represents a cutting-edge approach in the realm of graphic transfer technologies, enabling precise reproduction of detailed artwork onto fabric surfaces. By incorporating specialized films and inks, this method allows creators to push the boundaries of design while maintaining quality fidelity across diverse materials. As industry professionals seek to refine their skills, understanding the nuances of this printing variant is key; from fabric preparation to heat application techniques, each factor plays a vital role in the overall success of the print. Furthermore, familiarizing oneself with the right printing supplies and operational protocols will lead to enhanced performance and a superior output. In the sections that follow, we’ll outline innovative practices and insights aimed at maximizing the effectiveness of this remarkable printing method.

Exploring DTF Printing Techniques

DTF printing techniques involve a combination of advanced methods that are designed to enhance the quality of prints while making the process more efficient. One notable technique includes adjusting the ink density during the printing phase. Higher ink densities can lead to more vibrant colors, which is crucial for designs that require sharp contrast. Additionally, using multiple passes during the printing process can increase the depth and detail of the final product. This can particularly benefit intricate designs where fine details are a must.

Another essential technique is the pre-treatment and post-treatment of fabrics. Pre-treating fabrics with the correct chemicals ensures that the ink bonds effectively with the fabric fibers, which is vital for durability. Following the DTF printing process with the right post-treatment—such as additional curing or heat setting—can further lock in the colors and prevent fading over time. Mastering these DTF printing techniques not only results in superior quality prints but also extends the life of the printed garment.

Maximizing Your DTF Printing Process

To optimize DTF printing, it is essential to look closely at both the process and the materials used. One effective strategy is to ensure that your printer settings are correctly calibrated. This includes adjusting the ink flow and print speed to match the type of fabric you are printing on. By aligning these settings, you can maximize print quality and minimize wasted materials. Regular maintenance of your printer helps keep it running smoothly, enabling consistent production.

Moreover, experimenting with various DTF printing materials can significantly affect the outcome. For instance, using high-quality transfer films designed specifically for DTF applications can vastly improve the adhesion of prints to fabrics. By investing in premium DTF printing materials, you’ll not only achieve better results but also create a more reliable workflow that can elevate your printing business.

Understanding DTF Printing Materials

When diving into the world of DTF printing, understanding the various materials involved is paramount. The core components include the transfer films, inks, and adhesive powders, each playing a crucial role in the quality and durability of printed designs. High-quality transfer films with a robust release agent coating facilitate smooth transfers, while inks made for DTF printing are specifically formulated to provide vibrant colors and lasting performance.

Additionally, selecting suitable adhesive powders is vital for ensuring that prints adhere well to different fabric types. The right powder not only enhances the bond but can also improve the washability of the finished product. Employing the best DTF printing materials can elevate your output, making your prints stand out in the market, thus appealing to quality-conscious customers.

Essential DTF Printing Tips for Beginners

For those new to DTF printing, adopting a few essential tips can make a drastic difference in the quality of your prints. First, always perform test prints on materials similar to those intended for the final product. This allows you to fine-tune the printer settings, such as resolution and color profiles, ensuring that your final print matches your expectations. Keeping a record of successful test prints can serve as a valuable reference for future jobs.

Another imperative tip is to maintain a clean workspace and equipment. Regularly cleaning your printer heads and ensuring the workspace is free from dust will help prevent issues that can compromise print quality. Additionally, calibrating your printer settings regularly is recommended to ensure consistency across all prints, which is especially important when working on larger orders.

Best Practices for the Curing Process in DTF Printing

The curing process in DTF printing is vital for achieving durable and long-lasting prints. It’s important to optimize the temperature and duration settings of your heat press or curing oven. Generally, a temperature of around 320°F for a duration of about 12 to 20 seconds is sufficient, but this can vary based on the specific inks and transfer films used. Testing these settings will allow you to find the perfect balance for your specific setup.

Additionally, ensure that you properly monitor the curing process to prevent overheating, which can lead to burning the fabric or damaging the print. Implementing a trial-and-error method during the initial setup can help you get the curing process just right. Consistency will enhance print quality and garment durability, making your DTF prints more appealing to customers.

Leveraging Heat Press Techniques for Quality Results

Heat press techniques are critical in ensuring that DTF prints adhere correctly to fabrics. Applying the right amount of pressure and the correct time is paramount. For various fabric types, the pressure applied during the transfer should be adjusted accordingly. This ensures that the print adheres well without distorting the fabric, which is crucial for maintaining the garment’s quality.

Moreover, taking time to align your prints accurately before using the heat press can often save time and materials in the long run. Misalignment can lead to wasted transfers and additional costs. Therefore, taking the time to double-check placements will ensure that your prints are consistently neat, which contributes positively to the overall perception of your products.

Frequently Asked Questions

What are the basic techniques involved in the DTF printing process?

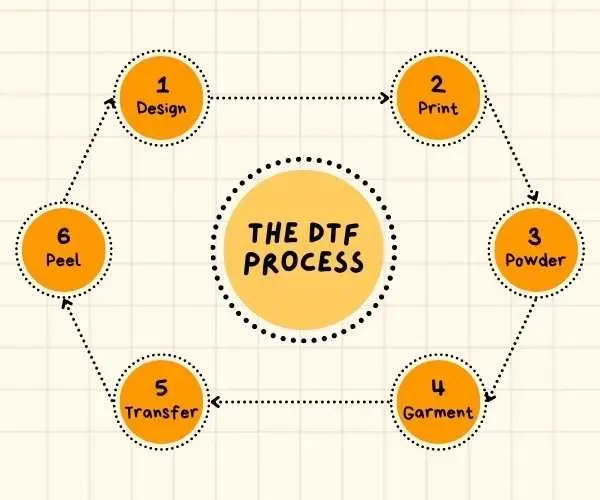

The DTF printing process involves several key techniques including printing designs onto a specialized transfer film, applying an adhesive powder, and using heat and pressure to transfer the design onto fabric. It’s essential to use high-quality DTF printing materials and maintain the right printer settings for optimal output.

How can I optimize the DTF printing process for better quality?

To optimize the DTF printing process, start by ensuring you use high-quality transfer films and inks specifically designed for Direct to Film printing. Adjust your printer settings for high resolution, calibrate color profiles, and properly treat fabrics before printing to achieve vibrant and durable designs.

What are the best tips for using adhesive powders in the DTF printing process?

When using adhesive powders in the DTF printing process, it’s crucial to apply them evenly and in the correct amounts on the wet film. Curing the adhesive properly is essential for strong bonding. Using a powder shaker can help achieve consistent coverage, thereby enhancing print quality.

What types of fabrics are best suited for DTF printing techniques?

DTF printing techniques work well on a variety of fabrics, including cotton, polyester, and blends. It’s important to understand the fabric’s properties as they react differently to Direct to Film printing materials. Pre-treating fabrics can also improve ink adhesion and vibrancy.

How does the curing process impact the DTF printing output?

The curing process is vital in the DTF printing workflow as it ensures the durability and viability of the print. The temperature and curing time must be carefully optimized according to the ink and film used to prevent fading and ensure long-lasting prints on garments.

What maintenance tips can improve my DTF printing process?

Regular maintenance is critical for a smooth DTF printing process. This includes cleaning the printer heads frequently to prevent clogs and calibrating printer settings to ensure consistent print quality. Additionally, conducting regular nozzle checks and keeping materials organized can enhance efficiency.

| Aspect | Key Points |

|---|---|

| Understanding DTF Printing | DTF printing involves transferring designs from a specialized film onto fabrics using heat and pressure. |

| Quality Materials | Use high-quality transfer films and specific DTF inks compatible with your fabrics. |

| Correct Printer Settings | Maintain the highest resolution and properly calibrated ICC profiles for accurate colors. |

| Pre-treatment of Fabrics | Evenly pre-treat fabrics to enhance ink adherence and prevent inconsistencies. |

| Curing Process | Optimize temperature and time during curing for a durable print. |

| Use of Adhesive Powders | Apply adhesive powder uniformly and cure it properly for strong bonding. |

| Heat Press Techniques | Ensure proper pressure and time, and check alignment before pressing. |

| Maintenance and Calibration | Regular cleaning and calibration of the printer maintain consistent quality outputs. |

| Experimentation | Conduct test prints and incorporate feedback for process improvement. |

| Training and Workshops | Invest in training through workshops and online courses to stay updated. |

Summary

The DTF printing process is an innovative printing method that offers exceptional quality and versatility for fabric applications. By mastering the various techniques associated with DTF printing, from selecting top-notch materials to executing precise heat press maneuvers, businesses can significantly enhance their output and product offerings. Consistency in pre-treatment, curing, and experimentation further contribute to achieving outstanding results. Continuous education through workshops and feedback integration ensures staying at the forefront of the printing industry. Ultimately, the DTF printing process enables artists and businesses alike to produce vibrant and durable designs that meet the evolving demands of the market.