DTF Gangsheet Builders are revolutionizing the world of custom apparel printing by enabling creators to push the boundaries of their designs. With the advancement of Direct-to-Film (DTF) printing, artists and businesses alike can explore vibrant color applications and intricate designs like never before. By utilizing gangsheet printing techniques, users can maximize their printing efficiency while minimizing material waste, making it a sustainable choice for custom garment production. This innovative technology opens a world of possibilities for unique apparel pieces that stand out in the crowded fashion market. As we delve deeper into the advantages offered by DTF gangsheet builders, prepare to unleash your creativity and transform your custom apparel vision into reality.

In the realm of creative garment printing, Direct-to-Film technology paired with gangsheet methodologies has become an essential tool for designers. Utilizing these advanced printing solutions, creators can execute their artistic visions while optimizing their resource usage. The synergy between DTF techniques and gangsheet layouts allows for diverse printing opportunities, paving the way for more efficient production processes. This not only caters to unique design needs but also enhances the overall quality and appeal of apparel outputs. Explore how these innovative printing methods can transform your custom clothing projects and elevate your artistic expression.

Understanding DTF Printing: A Comprehensive Overview

DTF printing, or Direct-to-Film printing, is revolutionizing custom apparel by allowing designers to print high-quality, vibrant images onto a range of fabrics. This method diverges significantly from traditional screen printing, offering unparalleled flexibility in terms of color and design intricacy. The process itself involves transferring ink onto a specialized film, which is then heat-pressed onto fabrics. This not only minimizes the challenges faced with color matching but also enables the incorporation of intricate designs that were previously deemed impractical.

The advantages of DTF printing extend beyond just aesthetic appeal. With its ability to conform to various fabric types—ranging from lightweight cotton to stretchy polyester—this technique meets the diverse needs of fashion designers and apparel producers alike. DTF’s high-quality output ensures that designs remain sharp, vivid, and durable, even after multiple washes, making it a preferred choice for brands aiming for longevity in their custom apparel.

Efficiency of Gangsheet Printing Techniques

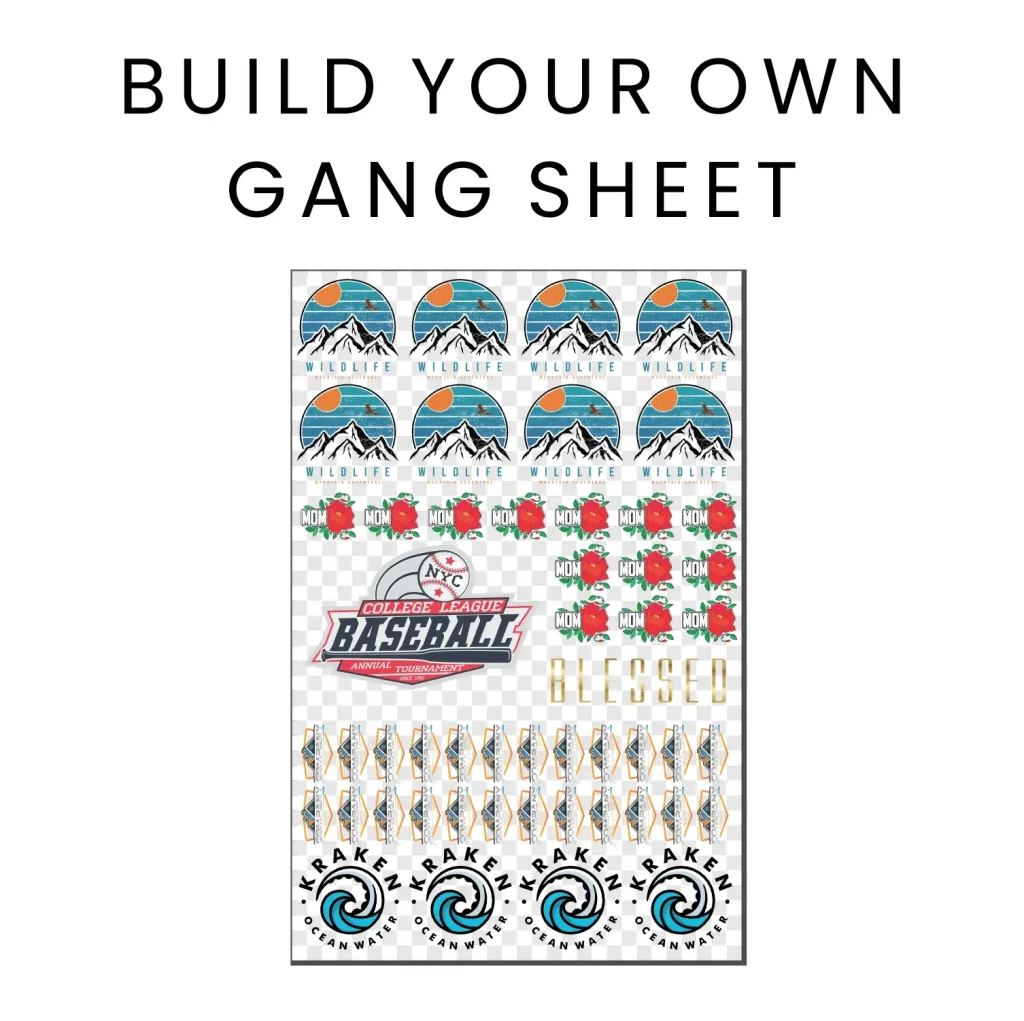

Gangsheet printing is a clever strategy employed in the DTF printing sphere that maximizes the use of print media while decreasing waste. By simultaneously printing multiple designs on the same film, creators can achieve an impressive volume of prints without the extensive material costs associated with traditional methods. This efficiency not only facilitates bulk production but also encourages designers to take more creative risks, knowing that they can experiment with several layouts simultaneously.

The typical advantages include a reduction in leftover materials and a streamlined workflow, crucial for small businesses and freelance artists who need to keep operations lean. Gangsheet techniques make it easy to coordinate various designs, allowing for experimentation with color placements, sizes, and styles all on one sheet. This collaborative approach fosters a unique opportunity for creativity, as artists can visualize their collections cohesively before final production.

Enhancing Creativity Using DTF Gangsheet Builders

DTF gangsheet builders are indispensable tools for anyone looking to elevate their custom apparel designs. These builders allow users to digitally arrange their designs for optimum layout before printing, providing ample room for artistic expression. By leveraging software that supports gangsheet layouts, designers can customize how their artwork interacts with one another—ensuring that alignments, proportions, and visual dynamics work in harmony on the final product.

Additionally, these builders facilitate the use of advanced design techniques, such as layering and color gradients, empowering creators to explore new visual styles. The ability to visualize complex designs digitally before they are committed to fabric removes much of the guesswork, ensuring that the final printed output reflects the designer’s true vision. This level of control fosters not just creativity, but also confidence in the printing outcomes.

Advanced Techniques for Optimizing DTF Printing

In the realm of DTF printing, ongoing advancements are critical for staying ahead in the competitive custom apparel market. Users are encouraged to adapt their practices by utilizing the latest printing technology, such as high-speed DTF printers that enhance production capabilities and ensure that color fidelity remains uncompromised. By incorporating improved models, designers can significantly increase their output while reducing turnaround times, leading to higher customer satisfaction and greater sales opportunities.

Moreover, integrating eco-friendly inks is becoming pivotal for many brands looking to appeal to a more environmentally-conscious audience. These water-based inks maintain vibrant colors while offering a lesser environmental footprint compared to traditional inks. As such, artists and designers are empowered to produce high-quality prints that not only look good but feel good to produce, appealing to consumers who prioritize sustainability in their purchasing decisions.

Creative Design Tips for Custom Apparel

When venturing into custom apparel design, creativity is paramount. Utilizing the DTF printing method opens up numerous possibilities for designers to experiment with textures, abstract patterns, and intricate graphics that were previously difficult to achieve. Consider merging various design elements that reflect your unique style or the brand’s ethos. Mixing playful motifs with serious themes can lead to striking visuals that resonate with target audiences.

Employing a mix of bold typography alongside illustrative graphics can also provide depth and break the monotony of conventional apparel designs. In addition, using unexpected color combinations can make a significant impact, drawing attention to your creations. With the versatility DTF printing offers, every design can be a canvas of its own—encouraging designers to push creative boundaries and craft pieces that stand out in the crowded apparel market.

Maximizing Output with DTF Gangsheet Strategies

To fully leverage the advantages of DTF gangsheet printing, strategic planning is key. Begin by carefully organizing your designs before creating a gangsheet to minimize any potential waste. Take the time to analyze your artwork, ensuring each piece complements the others when printed together. This not only maximizes the visual appeal of the gangsheet but also optimizes the material usage, leading to higher efficiency in the printing process.

Another effective strategy is to experiment with design placements on the gangsheet. Creative layout experimentation can lead to fresh and innovative presentations of your artwork. Think about patterns or arrangements that are unconventional; this could involve layering designs in both aligned and haphazard orders, helping you to stand out from the competition. Ultimately, the goal is to produce a product that not only meets production costs but also captivates your target clientele.

Frequently Asked Questions

What are DTF Gangsheet Builders and how do they work in custom apparel printing?

DTF Gangsheet Builders are specialized tools designed to create layouts for Direct-to-Film (DTF) printing. They allow users to combine multiple designs on a single sheet, optimizing the use of fabric and reducing material waste. This advanced printing technique enhances creativity by providing users the freedom to experiment with various designs, colors, and arrangements, resulting in unique custom apparel.

How does DTF printing differ from traditional printing methods?

DTF printing stands out from traditional methods, like screen printing, by enabling vibrant, multi-colored prints on various fabrics through a more straightforward process. Instead of using screens and setups for each color, DTF leverages special transfer films and heat application, allowing for complexity in design and versatility across materials. This technology both improves print quality and lowers production costs.

What are the benefits of using gangsheet printing techniques with DTF?

Employing gangsheet printing techniques with DTF offers numerous advantages, including increased efficiency, minimized waste, and enhanced creative possibilities. By printing multiple designs on one sheet, production becomes more streamlined, reducing overall costs. Additionally, this technique allows for creative freedom, enabling designers to showcase diverse styles without sacrificing material.

Why should I choose DTF printing for my custom apparel projects?

Choosing DTF printing for custom apparel offers several benefits, such as high-quality output with vibrant colors, versatility for a range of fabric types, and cost-effectiveness due to minimized setup requirements. DTF technology is ideal for any printing scale, especially for businesses looking to produce eye-catching designs quickly and efficiently.

What tips can help me succeed with DTF gangsheet printing?

To succeed with DTF gangsheet printing, it’s essential to test your designs first, understand proper heat press techniques, and maintain your DTF printer regularly. Producing test prints ensures color accuracy on fabric, while mastering the heat application process prevents printing mishaps. Consistent printer maintenance helps avoid clogs and ensures high-quality outputs.

How can I maximize creativity using DTF Gangsheet Builders?

You can boost creativity with DTF Gangsheet Builders by experimenting with design layering, adjusting sizes for optimal fit, and trying different materials and textures. Taking advantage of custom layouts allows for unique arrangements, enabling you to explore innovative design concepts and really push the boundaries of your custom apparel projects.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A modern printing technique allowing vibrant, multi-colored designs on various fabrics via heat and pressure application. |

| Benefits of DTF Printing | Includes versatility across fabric types, high-quality output with color accuracy, and cost-effectiveness due to simplified processes. |

| Understanding Gangsheet Printing | A method of printing multiple designs on a single sheet to optimize material usage and reduce waste. |

| Key Advantages of Gangsheet Technique | Enhances efficiency, reduces waste, and provides creative opportunities for combining different designs. |

| How DTF Gangsheet Builders Enhance Creativity | Tools that allow for layout design optimization, size adjustments, material experimentation, and unique arrangements. |

| Recent Technological Advances in DTF Printing | Includes improved printers, eco-friendly inks, and user-friendly design software that simplify the printing process. |

| Tips for Successful DTF Gangsheet Printing | Conduct test prints, correctly use heat presses, maintain printers, and seek feedback to refine designs. |

Summary

DTF Gangsheet Builders are revolutionizing the world of custom apparel printing by allowing users to merge creativity with technological advancements. This innovative approach not only enhances the efficiency of the printing process but also provides a vast canvas for artistic expression. By leveraging the power of DTF printing and gangsheet layouts, designers can explore limitless possibilities—from experimenting with unique arrangements to utilizing eco-friendly materials. This synergy between technology and creativity empowers custom apparel makers to produce stunning designs that captivate audiences while maintaining cost-effectiveness. As you dive deeper into the world of DTF Gangsheet Builders, remember that the key to success lies in constant experimentation and refinement of your craft.