In the rapidly evolving world of custom printing, the DTF Gangsheet Builder serves as a vital tool for creators aiming to streamline their design processes. This powerful software not only enhances DTF printing techniques but also optimizes the gang sheet layout to facilitate efficient printing methods. By enabling users to print multiple designs on a single sheet, the DTF Gangsheet Builder cuts down on both time and costs, making it a cost-effective printing solution for businesses of all sizes. In this article, we will uncover essential DTF printing tips to maximize your experience with this innovative tool. Whether you’re a seasoned printer or a newcomer, understanding the capabilities of the DTF Gangsheet Builder can elevate your print quality and expand your creative horizons.

When it comes to Direct to Film printing, utilizing a gangsheet builder can significantly enhance your production workflow. The ability to generate layouts with multiple designs on one single sheet is not only a practical solution but also a smart strategy for optimizing resources and minimizing waste. By mastering various DTF printing techniques, you can utilize this tool to its fullest, effectively managing print resources while maintaining the integrity of your designs. Furthermore, understanding the nuances of efficient printing methods will ensure that you achieve high-quality results with every print batch. Ultimately, leveraging these capabilities will set you apart in the competitive landscape of custom design printing.

1. The Power of the DTF Gangsheet Builder

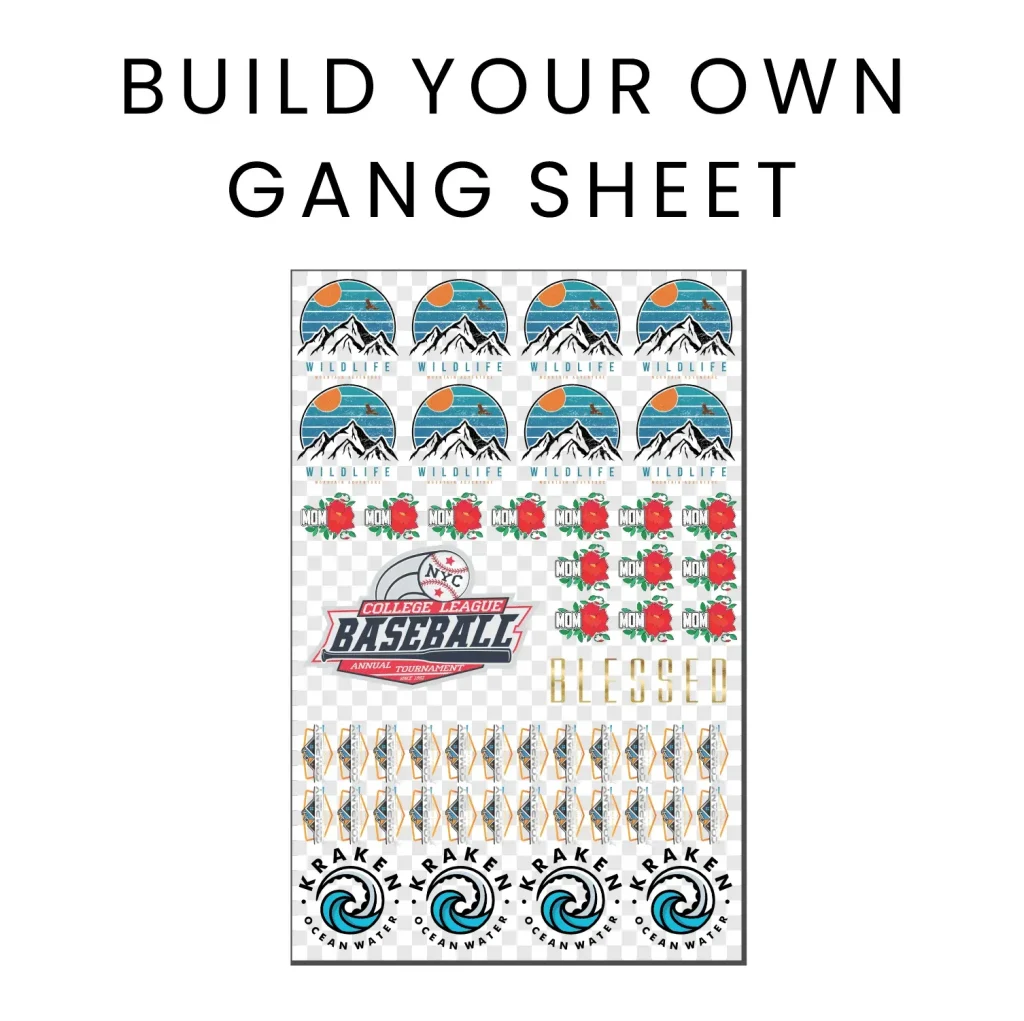

The DTF Gangsheet Builder is a revolutionary tool in the printing industry, offering a platform to optimize multiple designs using a single sheet of film. By effectively utilizing this builder, users can streamline their workflow, reduce printing costs, and maximize material usage. This method not only enhances the productivity of your printing tasks but also provides flexibility in handling different design orientations and sizes on the same sheet.

Furthermore, the DTF Gangsheet Builder promotes efficient printing methods by enabling you to run various designs in a single pass. This capability not only conserves resources but also minimizes the time spent transitioning between different design setups. With such advantages, it’s clear that investing time into mastering the DTF Gangsheet Builder is essential for any serious printer looking to elevate their output and efficiency.

2. Mastering DTF Printing Techniques for Optimal Results

To truly harness the potential of the DTF printing process, mastering effective printing techniques is crucial. Understanding features such as ink types, heat transfer settings, and film compatibility is essential for achieving vibrant and durable prints. Each DTF printer may have its unique characteristics, making it imperative to conduct thorough research and testing to determine the best techniques that align with your specific equipment.

Additionally, utilizing proper design techniques during the preparation stage—like vectorizing artwork and ensuring correct dimensions—can greatly enhance the printing outcome. By combining solid design principles with an understanding of the DTF printing techniques, printers can achieve professional-looking results that cater to a variety of markets.

3. Cost-Effective Printing Through Smart Gang Sheet Layout

Implementing a smart gang sheet layout can significantly impact your printing costs. By strategically placing multiple designs onto a single sheet, you can minimize waste and lower the expense of materials. This approach not only reduces the number of prints needed but also conserves ink and film, making your printing process more economical.

Moreover, an efficient gang sheet layout allows you to maximize every inch of your film. By carefully arranging images and ensuring the appropriate margins, you can produce more with less, making your operations more profitable. Cost-effective printing isn’t just about buying cheaper materials; it’s about optimizing every aspect of your workflow to ensure sustainability and profitability.

4. Tips for Efficient DTF Printing

Efficiency is key in the world of DTF printing, and following a set of proven tips can streamline your operations significantly. Ensuring that your workspace is organized and that all necessary tools and materials are easily accessible can save time during the production process. Additionally, maintaining a clean printing environment helps in reducing the risk of errors and defects, contributing to a smoother workflow.

Moreover, taking the time to establish a checklist for every print job—including design specifications and setting parameters—can simplify processes and mitigate mistakes. By fostering a culture of efficiency, both in operations and organization, you can maximize your printing capabilities and improve your overall productivity.

5. Staying Competitive with DTF Printing Community Insights

The DTF printing community is a valuable resource for printers seeking to stay updated on trends and best practices. Engaging with fellow printers through forums, social media groups, and local meetups can lead to the exchange of innovative techniques and troubleshooting tips that enhance your overall printing quality. The insights gained from these interactions can provide a competitive edge in a rapidly evolving industry.

Additionally, active participation in community discussions can inspire creativity and spark new ideas for design and printing techniques. By fostering connections with other DTF printing enthusiasts, you can continuously learn and adapt, ensuring that your printing methods remain relevant and effective as advances in technology and trends arise.

6. Importance of Material Compatibility in DTF Printing

Understanding material compatibility is a vital aspect of DTF printing that can make or break your print quality. Not all fabrics react the same with DTF inks and transfer films, making it essential to know which materials work best with your setup. From cotton to polyester blends, each type has its specific requirements regarding temperature and pressure during the heat transfer process, influencing both adhesion and vibrancy of print.

Moreover, investing time to test various materials can yield valuable insights into the best pairings for flawless results. As you experiment with different fabric types, you’ll not only enhance your print quality but also expand your product offerings, catering to diverse customer needs and preferences.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it enhance DTF printing techniques?

A DTF gangsheet builder is a tool designed to optimize the DTF printing process by allowing multiple designs to be arranged efficiently on a single sheet, known as a gang sheet. This enhances DTF printing techniques by maximizing material usage and minimizing wasted space, resulting in cost-effective printing.

What are effective DTF printing tips for using the gang sheet layout?

To optimize your DTF printing with a gang sheet layout, focus on arranging your designs to minimize gaps and ensure appropriate margins. Additionally, utilize software tools for visualization, regularly maintain your printer, and perform test prints to ensure quality before large batches.

How can I ensure efficient printing methods using a DTF gangsheet builder?

Efficient printing methods using a DTF gangsheet builder involve batch processing similar designs together to streamline adjustments and setups. Moreover, familiarize yourself with your printer’s specifications and regularly maintain your equipment for optimal performance.

What maintenance is required for a DTF printer used with a gangsheet builder?

Regular maintenance of your DTF printer is crucial for successful printing with a gangsheet builder. This includes cleaning the printheads and nozzles, checking ink levels, and ensuring that print settings are correctly configured for different materials to prevent defects.

What types of materials are best suited for DTF printing with the gangsheet builder?

For optimal results with a DTF gangsheet builder, it’s important to use fabrics that are compatible with DTF printing, such as cotton, polyester, and blends. Additionally, knowing the temperature and pressure requirements during heat transfer can significantly enhance print quality.

How can I keep updated on trends related to DTF printing and the gangsheet builder?

To stay informed about trends in DTF printing and best practices for using a gangsheet builder, participate in online forums, social media groups, and community discussions. Engaging with fellow printers provides valuable insights, tips, and troubleshooting advice that can enhance your DTF printing experience.

| Key Point | Description |

|---|---|

| Introduction | Overview of DTF printing and the significance of the DTF Gangsheet Builder. |

| DTF Printing Basics | DTF printing uses special film for transferring inks onto fabrics, allowing vibrant colors and durability. |

| Gang Sheet Technique | A method to print multiple designs on one sheet, saving time and materials. |

| Design Layout Optimization | Arrange designs efficiently to reduce waste and optimize material usage. |

| Understanding Print Settings | Adjust printer settings like resolution and color profiles for better print quality. |

| Regular Equipment Maintenance | Routine cleaning of printer components ensures consistent ink flow and print quality. |

| Utilize Test Prints | Conduct test prints to check color accuracy and layout before mass production. |

| Batch Processing | Reduce adjustments and enhance workflow efficiency by grouping similar prints. |

| Trend Updates and Community Engagement | Stay informed on DTF printing trends through forums and social media. |

| Effective Color Management | Use color management tools to maintain consistency across prints. |

| Material Compatibility | Know which fabrics work best with DTF printing to avoid quality issues. |

Summary

The DTF gangsheet builder is essential for optimizing your custom printing process. By focusing on efficient design layouts, understanding print settings, and maintaining your equipment, you can enhance your printing quality and productivity. Incorporating practices such as test prints and batch processing can streamline your workflow, while staying updated with community insights and color management will ensure top-notch results. Success in the DTF printing landscape is achieved through continued learning and effective resource management, enabling you to create stunning graphics that stand out.