The DTF Gangsheet Builder is revolutionizing modern fabric printing by merging innovation and efficiency in one powerful tool. This cutting-edge technology allows users to print multiple designs on a single sheet, optimizing both material usage and production time. Unlike traditional printing methods that often come with higher costs and longer setup times, DTF printing with gang sheets offers an exceptional cost-effective printing solution for businesses of all sizes. With the capability to produce high-quality prints on various fabrics, the DTF Gangsheet Builder is perfect for meeting diverse customer needs. As the demand for customization increases, this advanced approach positions itself as the preferred choice for forward-thinking entrepreneurs in the textile industry.

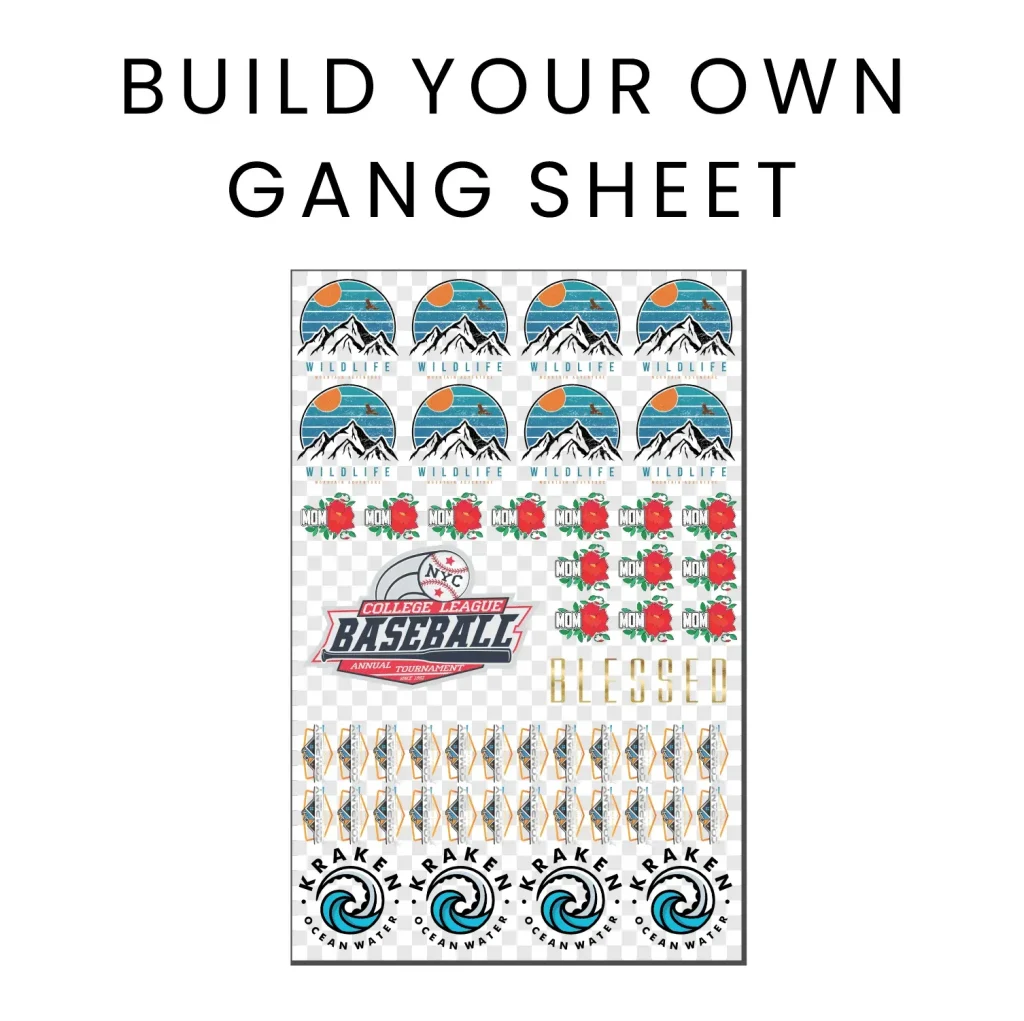

The DTF Gangsheet Builder, a game-changer in the fabric printing arena, presents an evolved alternative to conventional printing techniques often marked by their limitations. This innovative approach to Direct-to-Film printing simplifies the process of creating custom designs, allowing for simultaneous prints of various artworks on one large sheet—known colloquially as gang sheets. Emphasizing efficiency and reduced costs, DTF printing not only streamlines operations for small businesses but also enhances their ability to cater to unique customer preferences. With its noteworthy versatility across multiple fabric types and rapid production capabilities, the DTF Gangsheet Builder is fast becoming the go-to solution for modern print service providers looking to thrive in a competitive market.

Understanding DTF Printing Technology

DTF printing, or Direct-to-Film printing, has emerged as a groundbreaking technique in the fabric printing sector, bringing a wave of innovation that traditional printing methods struggle to match. By utilizing film as the substrate for printing designs, DTF offers a higher level of detail, vibrancy, and durability in printed fabrics. This modern approach contrasts sharply with traditional techniques, which may involve cumbersome setups and longer production times, making DTF a preferred choice for many businesses seeking both quality and efficiency.

Moreover, the technology embraces the concept of gang sheets, which allows multiple designs to be printed on a single sheet of film. Not only does this optimize the use of ink and materials, but it also reduces waste significantly. This is an especially crucial advantage for smaller businesses that may operate on tight budgets but still desire to offer a variety of products. As companies increasingly adopt DTF printing, it represents a pivotal shift towards creating high-quality products more sustainably.

The Advantages of the DTF Gangsheet Builder

The DTF Gangsheet Builder has revolutionized how businesses approach fabric printing, combining technology with efficiency to produce stunning results. By allowing multiple designs to be printed simultaneously on a single sheet, the gangsheet builder significantly reduces production times and costs. For businesses producing custom designs or limited runs, this technology offers a pathway to meet consumer demands without the traditional wait times associated with single-piece printing methods.

Furthermore, the ability to print smaller quantities with less waste is not only economically beneficial but also environmentally responsible. The DTF Gangsheet Builder empowers businesses to minimize their textile footprint while still delivering high-quality prints that meet their customers’ expectations for uniqueness and clarity.

Cost Comparison: DTF vs. Traditional Printing

When considering the financial implications of adopting DTF printing over traditional methods, the cost savings become apparent. The DTF process, particularly with the gangsheet approach, allows businesses to eliminate unnecessary expenses associated with setup and equipment maintenance required for traditional screen printing. This makes DTF an attractive option for startups and small to medium-sized enterprises looking to optimize their budget.

Additionally, because DTF prints can be produced in less time and with fewer resources, businesses report enhanced profitability when they switch to this method. The ability to generate multiple designs for various clients on one sheet means that printers can also expand their service offerings without incurring significant additional costs. This cost-effective approach aligns perfectly with the growing trend towards personalized fabric items.

Quality and Customization in DTF Printing

The quality of prints produced by DTF printing methods stands out in comparison to traditional practices. With modern DTF printers, detailed and vibrant designs become achievable even on a variety of fabric types, including cotton and polyester blends. This versatility allows businesses to cater to a wide demographic, ranging from custom t-shirt shops to specialized textile manufacturers looking for unique offerings.

Moreover, DTF technology emphasizes customization, enabling businesses to adapt quickly to changing consumer preferences. As customers increasingly seek bespoke and personalized products, the capability to print high-quality, individualized designs gives companies a competitive edge that traditional printing methods often lack.

Market Trends: The Growth of DTF Printing

The growth of DTF printing in the textile market has been impressive, with more businesses recognizing the potential and versatility of this method. Industry reports indicate that advancements in DTF technology are fostering increased adoption, as companies look to modernize their operations and respond to consumer demands for quicker and more unique products. Companies like Eazydtf have expanded their fleets, indicating strong confidence in the future of DTF.

As more businesses shift towards DTF printing, it is becoming clear that the technique not only fulfills the needs for efficiency and quality but also aligns with the modern consumer’s desire for customization and rapid turnaround times. This trend is shaping a new fabric printing landscape where DTF doesn’t just compete with traditional methods; it sets a new standard.

Empowering Small Businesses Through DTF Technology

One of the most significant impacts of DTF printing is its accessibility for smaller businesses and entrepreneurs. Traditional printing technologies often require high upfront investments and maintenance costs, creating barriers for many. However, the entry of user-friendly and compact DTF printers has democratized the textile printing market, allowing even home-based operations to thrive.

This newfound accessibility means that entrepreneurs can experiment with designs, cater to niche markets, and adjust swiftly to changes in consumer demand without needing significant financial resources. By leveraging DTF printing, small businesses can effectively compete with larger firms, utilizing advanced technology to enhance their offerings and customer satisfaction.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it operate?

The DTF Gangsheet Builder is a specialized tool designed for creating gang sheets in Direct-to-Film (DTF) printing. It allows users to arrange multiple designs on a single sheet to optimize material usage and minimize waste. This innovative system streamlines the printing process, making it highly efficient and cost-effective compared to traditional printing methods.

How does DTF printing with gang sheets compare to traditional printing methods?

DTF printing using gang sheets offers substantial advantages over traditional methods. Unlike traditional printing that requires separate setups for each design, gang sheets enable simultaneous printing of multiple designs, significantly reducing material waste and lowering production costs. This efficiency is ideal for businesses looking to enhance their printing operations.

What are the benefits of using a DTF Gangsheet Builder for small businesses?

Small businesses benefit immensely from the DTF Gangsheet Builder, as it provides a cost-effective printing solution with high-quality outputs. By utilizing gang sheets, smaller operations can achieve lower setup costs, minimize ink usage, and fulfill diverse customer demands without the need for extensive investments in traditional printing equipment.

Can DTF printing handle various fabric types, and what makes it versatile?

Yes, DTF printing is highly versatile and can print on various fabric types, including cotton, polyester, and blends. The DTF Gangsheet Builder allows businesses to customize designs for different materials, effectively catering to a wide range of applications, from customized apparel to specialized cloth products.

What are the industry trends with DTF Gangsheet Builders and their impact on printing?

Recent trends show a growing adoption of DTF Gangsheet Builders in the printing industry as more businesses recognize their efficiency and quality benefits. The continuous investment in DTF technology is revolutionizing fabric printing, enabling faster turnaround times and higher customization levels, positioning DTF as a preferred choice over traditional methods.

Is DTF printing more accessible for new entrepreneurs compared to traditional printing?

Absolutely. DTF printing, facilitated by gang sheets, has become more accessible for new entrepreneurs due to the availability of compact and affordable printers. This shift allows small-scale operations to enter the printing market without significant upfront costs associated with traditional printing methods, fostering a competitive environment.

| Key Point | DTF Gangsheet Builder | Traditional Printing |

|---|---|---|

| Efficiency and Cost-Effectiveness | Allows simultaneous printing of multiple designs on one sheet, reducing ink and material waste, ultimately lowering costs. | Requires separate setups for each design, leading to higher operational costs and material waste. |

| Quality and Versatility | Produces vibrant colors and intricate details on various materials (cotton, polyester, etc.), ideal for custom, small production runs. | Typically limited to a fewer range of materials and often lower quality compared to modern DTF printing. |

| Industry Trends and Innovations | Rapid advancements in DTF technology, increasing production capacity and meeting high demand for quality and quick turnaround times. | Slower to innovate, facing increased pressure from DTF printing advancements. |

| Accessibility for Smaller Businesses | Affordable, compact printers are now available, enabling small businesses to compete without heavy investment. | Typically requires significant machinery investment, acting as a barrier for smaller enterprises. |

Summary

The DTF Gangsheet Builder represents a transformative step forward in the world of textile printing, standing out as a superior choice compared to traditional printing methods. This innovative technology not only boosts efficiency and lowers production costs but also ensures high-quality outcomes across a variety of fabrics. With its adaptability and accessibility for small businesses, the DTF Gangsheet Builder empowers new players to thrive in an increasingly competitive landscape. As the industry shifts towards personalized products and rapid delivery, the advantages provided by DTF printing models become indispensable, cementing their role as a staple in modern printing solutions.