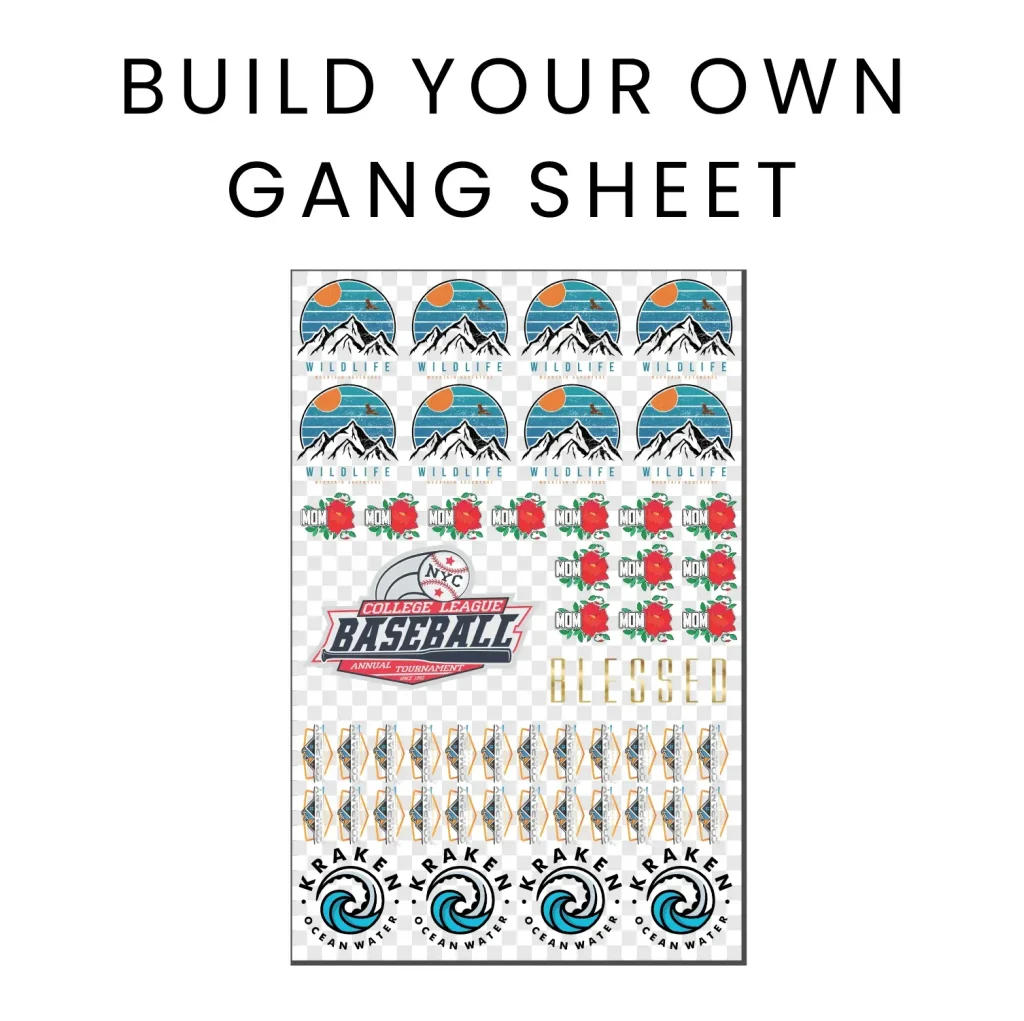

The DTF Gangsheet Builder is revolutionizing the world of Direct-to-Film printing, providing innovative solutions to maximize printing efficiency. This specialized software allows users to create optimal gangsheet layouts, significantly reducing waste and costs while increasing productivity. By intelligently arranging multiple designs on a single film sheet, businesses can take full advantage of their printing materials and streamline workflows. With the right DTF printing software, you can ensure that every inch of the film is utilized effectively, leading to enhanced DTF printing optimization. Embracing the capabilities of a DTF Gangsheet Builder not only elevates operational performance but also gives you a competitive edge in the fast-paced print production industry.

Introducing the concept of a DTF Gangsheet Builder involves understanding its role in the Direct-to-Film printing landscape. This advanced design software serves to enhance the layout process, enabling print service providers to maximize efficiency by arranging various designs strategically on a single sheet. By utilizing a gangsheet layout, companies can minimize material waste, save on costs, and improve overall workflow. Such tools are invaluable for anyone looking to optimize their printing process, utilizing advanced DTF printing software designed to streamline and enhance productivity. With the rise of demand for efficient printing solutions, exploring gangsheet builders is an essential step for any modern print business.

The Importance of DTF Gangsheet Builders in Printing Efficiency

In the world of Direct-to-Film (DTF) printing, efficiency is not just a goal; it’s a necessity. DTF gangsheet builders play a crucial role in achieving this efficiency by enabling businesses to arrange multiple designs on a single sheet of film. By optimizing the gangsheet layout, printers can significantly reduce material waste, leading not only to cost savings but also to a faster turnaround time for orders. These specialized tools leverage innovative algorithms to calculate the most space-efficient layouts, allowing businesses to maximize their output with minimal resources.

Furthermore, the deployment of DTF gangsheet builders transforms how print operators perceive their workflow. Rather than seeing printing as a series of individual jobs, it becomes a seamless process where multiple designs can be produced simultaneously. This approach not only saves time and materials but also enhances productivity by minimizing setup times between prints. As companies become increasingly competitive in the DTF space, adopting such intelligent solutions is paramount for sustaining growth and profitability.

Strategies for Effective Design Optimization

Effective design optimization is central to maximizing your DTF printing capabilities. To begin, businesses should invest in understanding the nuances of image layout; choosing the right dimensions for designs and strategically adjusting spacing can lead to significant improvements in material usage. By ensuring that images are placed close together without overlap, you minimize waste and create an efficient gangsheet layout, which is essential for maintaining a sustainable operation. This attention to detail not only streamlines the production process but also enhances the overall aesthetic quality of the final product.

Moreover, variability in design sizes—integrating both small and large graphics—can greatly enhance the utility of film sheets. This flexibility allows businesses to cater to diverse customer requirements without the need for reconfiguring setups frequently. The ability to batch different sizes together promotes operational agility and can lead to higher customer satisfaction as orders are fulfilled with unprecedented speed and efficiency. Utilizing software tools dedicated to DTF printing can further enhance these strategies, making it easier to manage complex design configurations.

Batch Processing: A Key Element of Efficiency

Batch processing stands out as a vital strategy for enhancing printing efficiency in DTF workflows. By grouping similar designs together, print operators can significantly reduce the setup time required for each individual job, thereby creating a smoother workflow. This method is especially beneficial in environments where volume and variety are constants, as it allows for maximizing the ink and materials used throughout the process, resulting in cost-effective operations. Furthermore, consistent handling of similar designs contributes to uniformity in the quality of the prints, which is crucial for maintaining client trust and brand reputation.

High-quality DTF printing software often comes equipped with features that facilitate batch processing. These tools allow users to easily manage multiple designs, automate placements, and adjust layouts with drag-and-drop functionalities. By tapping into these innovative software solutions, print services can not only improve their operational efficiency but also drastically cut down the average time required from design to production. As businesses navigate through increased demands, utilizing batch processing techniques positions them for sustained success and adaptability in the competitive DTF landscape.

Leveraging DTF Software for Workflow Optimization

Choosing the right DTF printing software is fundamental to optimizing workflow and enhancing productivity. Programs like **Cinco**, **GooseGang**, and **Bling** are specifically tailored to meet the needs of modern DTF printers, effectively streamlining the design layout process. These platforms offer user-friendly interfaces with functionalities designed to simplify gangsheet creation, such as automatic image resizing, placement suggestions, and real-time previews. As a result, operators benefit from substantial time savings and reduced error rates in design setups, allowing for a more efficient production process.

Moreover, investing in these sophisticated DTF printing applications ensures quality control is embedded within the workflow. Many of these solutions incorporate built-in quality checks that flag potential issues in designs before they proceed to print, mitigating the risks of wasted materials and costly reprints. With the combined efficiency of fast design setup and maintaining high print quality, businesses can uphold their reputation, increase throughput, and ultimately drive profitability in their DTF printing efforts.

Ensuring Quality Control in DTF Printing

Quality control is a critical factor that directly impacts printing efficiency, particularly in the realm of DTF printing. Regular calibration of printers is essential to ensure that outputs consistently meet the desired quality standards. The use of superior-quality films cannot be overstated; overlooked material choices often result in compromised prints, necessitating expensive reprints that reduce profit margins. Establishing a strict inspection regimen can help businesses capture potential errors early in the process, ensuring that DTF gangsheet builders function as intended and that the final products meet both business and customer expectations.

Additionally, implementing routine quality assessments throughout the entire printing process, from initial design to final prints, guards against the myriad factors that can lead to material waste and increased production costs. By focusing on continuous quality improvement, print businesses not only enhance operational efficiency but also establish a reputation for excellence in their products, gaining competitive advantages in the DTF market.

Post-Processing Techniques That Enhance Efficiency

Post-processing is an often-overlooked stage in the DTF printing workflow that holds immense potential for enhancing overall production efficiency. After printing, ensuring proper curing of prints and the precise application of powder adhesives are crucial for the longevity and quality of the final product. Streamlined post-processing techniques that are standardized can significantly reduce turnaround times, leading to improved productivity in fulfilling customer orders. By investing in automated curing and adhesive application systems, businesses can create a more efficient workflow while guaranteeing that quality remains uncompromised.

Furthermore, optimizing the post-processing phase is essential for meeting rising consumer expectations for fast delivery and high-quality products. Keeping abreast of advancements in curing technologies or adhesive solutions can provide competitive advantages, positioning businesses as leaders in the DTF printing space. By tightly integrating post-processing techniques with efficient DTF gangsheet builders, print shops can achieve not just speed but consistent quality output that resonates with the market’s demands.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it improve printing efficiency?

A DTF Gangsheet Builder is a specialized software that optimizes the arrangement of multiple designs on a single Direct-to-Film (DTF) sheet. By maximizing the use of film space, it reduces material waste and enhances printing efficiency, allowing print businesses to produce multiple designs in one pass.

How can I optimize gangsheet layouts for better DTF printing results?

To optimize your gangsheet layouts, ensure images are placed closely without overlapping, adjusting dimensions for efficient use of film space. Incorporate various design sizes to best utilize the printing surface, maximizing efficiency and allowing for flexibility in fulfilling orders.

What role does DTF printing software play in enhancing production workflows?

DTF printing software simplifies the design layout process by offering features like drag-and-drop functionalities and automated placement suggestions. High-quality software helps reduce setup time, enhances print quality, and streamlines workflows, significantly improving overall production efficiency.

What are the benefits of batch processing in DTF printing using a gangsheet builder?

Batch processing allows you to group similar designs together, minimizing setup time and maximizing ink usage. This method not only speeds up the printing process but also ensures consistent quality across multiple prints, contributing to greater printing efficiency.

How can I ensure quality control while using a DTF gangsheet builder?

To ensure quality control, regularly calibrate your DTF printer and use high-quality films. Implement a routine inspection process to verify that prints meet quality standards and check that designs are optimized for printing using your gangsheet builder.

What are the latest trends in DTF printing that can impact gangsheet building?

Current trends in DTF printing include eco-friendly inks and materials, which cater to the growing demand for sustainable practices. Staying informed about innovations in the DTF community can enhance your use of gangsheet builders, resulting in efficient, high-quality prints that resonate with environmentally conscious consumers.

| Key Point | Details |

|---|---|

| Understanding DTF Gangsheet Builders | Innovative software solutions that optimize design arrangement on a single film sheet, reducing waste and enhancing workflow. |

| Design Optimization | Ensure images are closely placed to minimize unused sheet areas while incorporating various design sizes for better space utilization. |

| Batch Processing for Efficiency | Group similar designs to reduce setup time and maximize ink and material usage, contributing to consistent quality. |

| Utilizing DTF Software Efficiently | Investing in quality software reduces design layout time and enhances quality checks before printing. |

| Focus on Quality Control | Regular printer calibration and using high-quality films prevent inferior prints and material waste. |

| Streamlined Post-Processing | Proper curing and application of adhesives impact the quality and longevity of prints. |

| Recent Developments in DTF Printing | Engage with online resources for tutorials and innovative practices, while focusing on sustainable printing methods. |

Summary

DTF Gangsheet Builder is an essential tool for maximizing your printing efficiency. By effectively utilizing the advanced features of gangsheet builders, print businesses can achieve remarkable reductions in costs and waste, while simultaneously improving productivity and output quality. The strategic use of these tools streamlines workflows and enhances design optimization, giving businesses the competitive edge they need in today’s fast-paced print production market. Embrace these techniques to elevate your DTF printing endeavors.