DTF Transfers, or Direct-to-Film transfers, are revolutionizing the landscape of custom apparel businesses by offering an innovative printing technology that enhances creative possibilities. This method enables entrepreneurs to achieve high-quality prints with striking vibrancy and detail, making it ideal for a diverse range of fabrics, from cotton to leather. As the demand for personalized fashion continues to grow, understanding the benefits of DTF transfers can position your brand as a leader in the competitive market. Whether you’re a seasoned business owner or just starting, this advanced printing technique is an essential tool for elevating your offerings and attracting customers. Explore how DTF transfers can transform your operations and inspire new creative ventures in fashion printing.

Alternative terms for DTF Transfers include Direct-to-Film printing, a modern method that streamlines the process of applying designs to fabrics. This innovative printing technology empowers entrepreneurs in the custom apparel business to create stunning and durable products with ease. Utilizing a straightforward application method, DTF printing caters to a wide variety of materials, enhancing versatility in fashion printing. Moreover, the entrepreneurial insights gained from adopting such a cutting-edge technology can lead to increased profitability and efficiency in operations. Embracing DTF as part of your business strategy can open doors to new market opportunities and elevate your brand’s presence in the fashion industry.

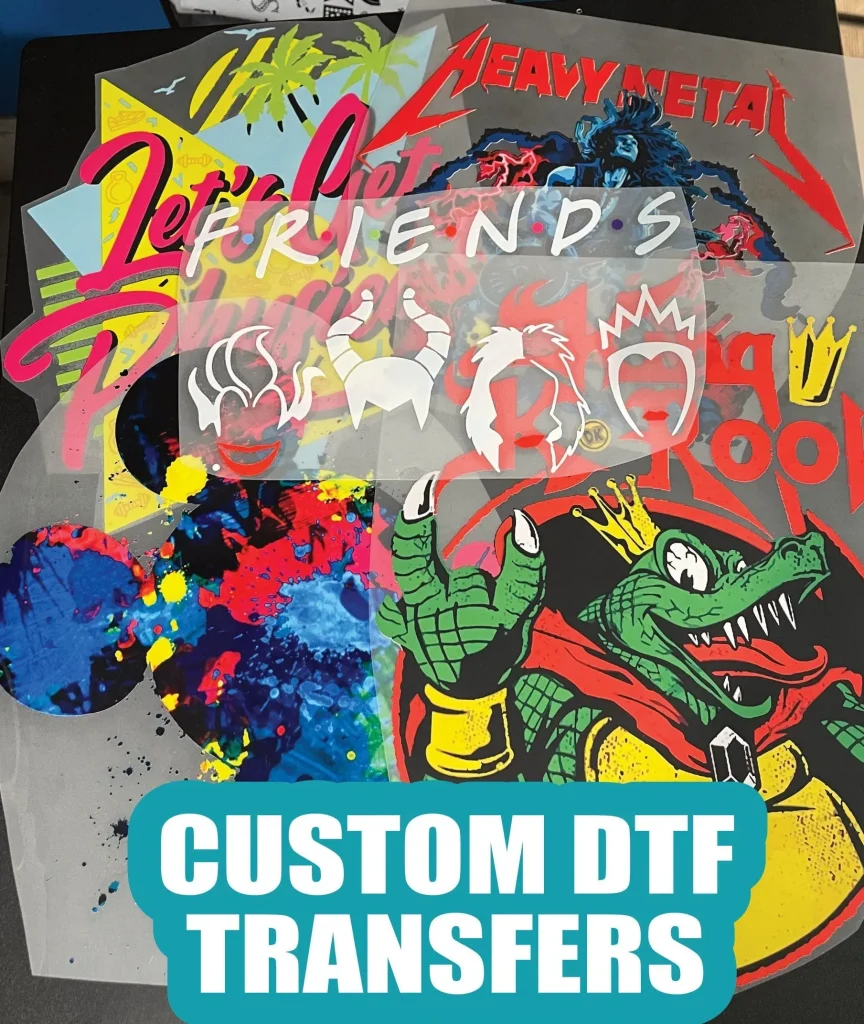

Understanding DTF Transfers: The Basics

DTF transfers, or Direct-to-Film transfers, represent an innovative printing process that has revolutionized how designs are applied to fabric. In essence, the designs are printed onto a special film, which can then be transferred onto various textiles using heat. This technique is highly versatile and can effectively produce designs on an array of materials, from cotton and polyester to leather and more. As the demand for customized items grows within the fashion industry, understanding the mechanics of DTF transfers becomes increasingly crucial for entrepreneurs looking to innovate.

This printing technology diverges significantly from traditional methods like screen printing and direct-to-garment printing, which often have limitations concerning fabric types and batch sizes. One of the appealing aspects of DTF is that it enables entrepreneurs to produce vibrant, high-resolution designs that are not only visually striking but also durable, allowing fabrics to withstand multiple washes without fading. For businesses venturing into custom apparel, mastering DTF transfers becomes a vital strategy for maintaining a competitive edge.

The Role of DTF Transfers in the Custom Apparel Industry

In the realm of custom apparel, the utilization of DTF transfers has become a cornerstone for many small businesses, allowing them to expand their product offerings without the overheads often associated with traditional printing methods. DTF transfers support low minimum order quantities, enabling entrepreneurs to test unique designs or cater to niche markets without the financial risks of holding large inventories. This flexibility not only makes DTF an appealing option for startups but also assists established brands in refreshing their product lines regularly.

Moreover, as fashion trends fluctuate rapidly, DTF transfers allow for a swift response to market demands. Entrepreneurs can capitalize on trending designs by quickly printing limited runs that meet consumer preferences. The ability to diversify product ranges—offering everything from sports apparel to chic fashion items—furthers the capabilities of a custom apparel business, positioning it favorably in a competitive marketplace.

Benefits of High-Quality Output with DTF Printing

One of the foremost advantages of utilizing DTF transfers is the high-quality output that can be achieved using this technology. When executed properly, DTF transfers yield vivid colors and intricate details, providing a premium finish that rivals traditional printing techniques. This is particularly essential in the custom apparel industry, where the visual appeal of products can significantly influence customer purchasing decisions.

Furthermore, entrepreneurs benefit from a consistent quality of output, which fosters trust and loyalty among customers. When consumers receive beautifully printed apparel that stands up to wear and washing, they are more likely to return for future purchases. As a result, embracing DTF printing not only enhances the perceived value of products but also reinforces brand reputation—critical components for success in today’s competitive fashion landscape.

Emerging Trends in DTF Printing Technology

The landscape of DTF printing technology is rapidly evolving, ushering in new trends that promise to enhance productivity and efficiency for small business owners. Recent advancements have led to improved ink formulations that offer better color vibrancy and fabric adherence, minimizing maintenance needs and elevating the quality of prints. For entrepreneurs, keeping abreast of these developments is essential, as it could mean the difference between outdated methods and cutting-edge solutions that appeal to modern consumers.

Moreover, manufacturers are concentrating on creating user-friendly devices that allow even novices in the printing space to harness the power of DTF transfers. These advancements reduce barriers to entry for aspiring entrepreneurs, allowing them to enter the custom apparel market without extensive experience or training. The combination of technology and accessibility positions DTF printing as a reliable choice for future-driven businesses aiming to innovate their product offerings.

Implementing Best Practices for DTF Transfers

For entrepreneurs looking to integrate DTF transfers into their operations, adhering to best practices is crucial for enhancing quality and efficiency. One significant aspect is to invest in high-quality equipment, including top-tier printers and inks. While upfront costs may be high, the long-term benefits—through enhanced output quality and reduced operational issues—justify this initial investment.

Another best practice involves comprehensive staff training on the DTF process. Ensuring that employees understand each stage of producing DTF transfers can dramatically improve the final product’s quality. This investment in education not only boosts operational efficiency but also fosters a knowledgeable workforce capable of addressing any potential issues that may arise during production.

Challenges in Adopting DTF Transfers

While the benefits of DTF transfers are substantial, entrepreneurs should be mindful of certain challenges that accompany adopting this technology. One of the most significant hurdles is the initial setup costs associated with acquiring quality equipment and materials. Entrepreneurs must prepare for these expenses and ensure that the long-term advantages of utilizing DTF outweigh the upfront financial output.

Moreover, handling DTF transfers requires careful attention to preserve their quality. Ensuring that printed transfers are managed delicately can mitigate damage and uphold product standards. Establishing thorough protocols for printing as well as packaging and shipping is essential to maintaining the integrity of the final product, which ultimately affects customer satisfaction.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, are a revolutionary printing technology where designs are printed onto a special film before being applied to fabrics with heat and pressure. This process allows for vibrant and durable prints that can adhere to various materials like cotton and polyester, making it ideal for custom apparel businesses.

What are the benefits of using DTF Transfers for custom apparel production?

Using DTF Transfers in custom apparel production offers numerous benefits, including cost-effectiveness with low minimum orders, versatility across various fabrics, and high-quality output. Entrepreneurs can cater to diverse markets without huge investments in multiple printing methods, ensuring vibrant designs that stand out.

How do DTF Transfers compare to other printing technologies?

DTF Transfers offer several advantages over traditional printing methods like screen printing and direct-to-garment printing. They provide high-quality, detailed prints on a range of materials, allow for smaller production runs, and require less setup time, making them ideal for entrepreneurs in the custom apparel business.

What challenges might entrepreneurs face when adopting DTF Transfer technology?

Entrepreneurs may encounter challenges with DTF Transfers, including initial setup costs for quality equipment and the need for careful handling of the transfers post-printing. However, the long-term benefits of high-quality, versatile output often outweigh these initial hurdles.

Which materials can be effectively printed using DTF Transfers?

DTF Transfers are highly versatile and can be effectively printed on various materials, including cotton, polyester, leather, and blends. This capability allows custom apparel businesses to meet diverse customer preferences and expand their product offerings.

What best practices should entrepreneurs follow when implementing DTF Transfers in their business?

Entrepreneurs should invest in quality equipment, provide proper training to staff, and maintain hygiene standards in the printing area. Adopting these best practices ensures high-quality DTF outputs and enhances customer satisfaction, leading to repeat business in the custom apparel market.

| Key Point | Description |

|---|---|

| DTF Transfers Overview | Printing designs onto special film for various fabrics using heat and pressure. |

| Cost-Effectiveness & Low Minimums | Allows low-volume runs, reducing inventory costs and aiding in market testing. |

| Versatility Across Materials | Effective on various fabrics from cotton to leather, catering to diverse customer needs. |

| High-Quality Output | Produces vibrant, detailed prints that rival traditional printing methods. |

| Market Trends | Growing demand for custom apparel driving expansion in the DTF market. |

| Technological Advancements | Improved quality and simplified user-friendly equipment for entrepreneurs. |

| Best Practices | Invest in quality equipment, provide staff training, and maintain hygiene standards. |

| Challenges | Initial setup costs and careful handling of transfers are critical considerations. |

Summary

DTF transfers can revolutionize your business by providing innovative solutions for custom apparel production. This advanced printing technology not only enhances product offerings but also allows for cost-effective production with high-quality results across various fabrics. With market trends indicating a rising demand for customized products, adopting DTF transfers now positions entrepreneurs to thrive. By leveraging the many benefits of DTF transfers, including their versatility, quality, and efficiency, businesses can enhance their creative capabilities and increase profitability. Embrace this transformative method today and watch your entrepreneurial endeavors flourish!