The DTF Gangsheet Builder is revolutionizing the world of custom apparel printing, allowing users to streamline their design process while maximizing print efficiency. With the rise of Direct-to-Film (DTF) printing, this innovative tool facilitates the compilation of multiple designs onto a single gangsheet, ensuring that every inch of material is utilized effectively. The result is not only a cost-saving solution but also an opportunity for creators to explore vibrant and intricate apparel design printing. This guide will equip you with essential DTF printing tips and techniques that enhance your DTF gangsheet design, ensuring optimal print optimization with every project. Join us as we delve into strategies that help you master this exciting printing technique and produce stunning designs.

The DTF Gangsheet Creator serves as a powerful asset for anyone involved in the world of apparel customization, simplifying the journey of design compilation. With the advent of Direct-to-Film technology, this remarkable software enables artists to bring together various graphic elements efficiently on one sheet of transfer film. Whether you’re a novice or an experienced printer, understanding the nuances of gang sheet development can lead to significant enhancements in your printing projects and overall workflow. This exploration will unveil effective methods for utilizing this tool while exploring critical aspects like color accuracy and design layout for successful printing outcomes. Don’t miss the chance to elevate your custom garment printing ventures with insightful knowledge surrounding DTF techniques and design optimization.

Maximizing Efficiency with DTF Gangsheet Builder

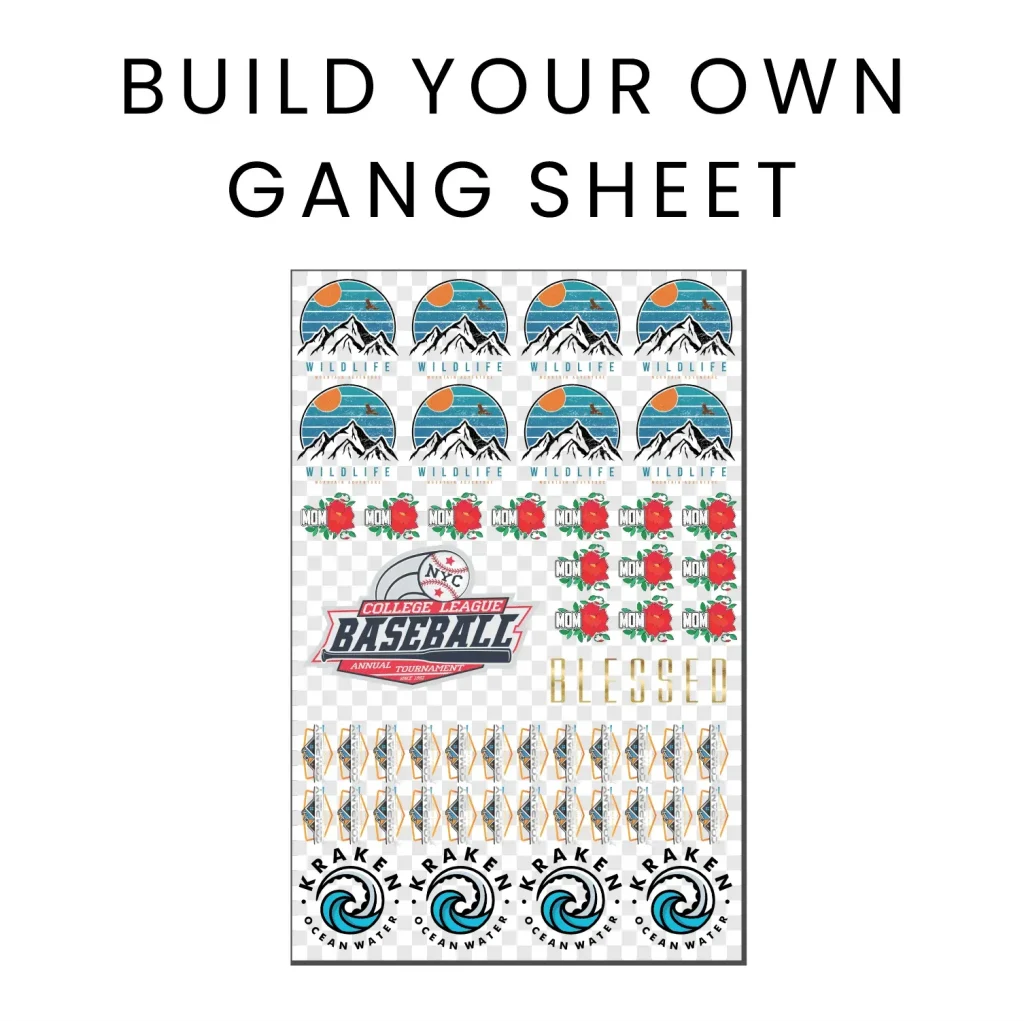

When using a DTF gangsheet builder, efficiency is key for custom apparel printing. This innovative tool allows you to combine multiple designs onto a single sheet, resulting in significant savings on material costs and a streamlined production process. By optimizing the layout of each design, you can ensure that every inch of the sheet is utilized effectively, minimizing waste while maximizing output. For instance, arranging smaller designs in a grid formation can significantly increase the number of prints you can produce, making your workflow more efficient.

In addition to layout optimization, exploring the capabilities of your DTF gangsheet builder can lead to enhanced production speed. Many modern builders come equipped with features that allow for instant adjustments, making it easy to resize or reposition designs on the fly. Moreover, familiarizing yourself with these functionalities can help you avoid common pitfalls, such as misalignment or poor scaling, which may compromise the quality of final prints. With the right approach, the DTF gangsheet builder becomes a powerful ally in your custom apparel printing journey.

Essential DTF Printing Tips for Success

To achieve optimal results in DTF printing, knowing a few essential tips can make all the difference. One crucial aspect is selecting the right DTF inks, specifically designed for transferring vibrant images onto various textiles. Ensuring that your inks complement your fabric choice can help achieve richer colors and better adherence. Additionally, keep in mind that temperature settings on your heat press are critical; incorrect temperatures can lead to poor adhesion or even damage to the fabric.

Another essential DTF printing tip is to pay attention to color calibration. Misalignment between your screen colors and the output can be frustrating, especially when working with detailed designs. To prevent this, consider using specific color profiles tailored for your printer model; this will help maintain consistency across all print runs. Investing time in pre-print tests can also allow you to adjust settings for maximum precision, ensuring your final designs stand out as intended.

Streamlining Your Design Layout for DTF Efficiency

When it comes to DTF apparel design printing, layout is everything. A properly organized design layout not only contributes to a clean finished product but also enhances efficiency during the printing process. It’s advisable to utilize templates provided by your DTF gangsheet builder, as these often include guidelines for optimal spacing and alignment. Consider using a grid layout to position designs close together, which not only maximizes the number of prints but also minimizes the excess material wasted around designs.

Moreover, adjusting the size of your designs appropriately can vastly improve your printing efficiency. Scaling down designs that need to fit snugly in certain sections of the gangsheet helps you utilize all available space. Always make a habit of checking the resolution of your designs before printing, as high-resolution files (300 dpi or higher) are essential to maintaining clarity and vibrancy in details. Mastering your layout can lead to a more productive and less wasteful printing experience.

Understanding Color Calibration for DTF Printing

Color calibration is a vital part of the DTF printing process that guarantees the final product meets your design expectations. Variations in printer types and inks can lead to discrepancies in color output, thereby affecting the overall appearance of your custom apparel prints. To prevent this, make it a point to familiarize yourself with the specific color profiles suited to your DTF printer. This can vastly improve color consistency across different batches.

Incorporating proper color management techniques, such as using calibrated monitors and printing from design software that supports color profiles, will also enhance color accuracy. Regularly checking and adjusting your color profiles according to the specific inks and fabrics being used can help achieve vibrant, true-to-design colors in your prints. Essentially, investing in thorough color calibration practices will save time and improve the quality of your end products.

The Importance of Conducting Test Prints

Conducting test prints before final production runs is a step that shouldn’t be overlooked in DTF printing. Test prints allow you to assess the quality and accuracy of color and design elements, helping to identify any issues that might arise when printing on a larger scale. By taking the time to conduct preliminary tests, you can adjust settings or make necessary design tweaks that ensure that your final prints turn out as expected.

Another benefit of test printing is that it can prevent costly errors. A small test run can reveal misalignments or issues with material adhesion that might lead to the entire batch being rejected. Engaging in this practice ensures that you maintain high standards for all your custom apparel prints, saving both time and resources while achieving consistently better results.

Leveraging Software Tools for Effective DTF Printing

In the world of DTF printing, leveraging the right software tools can significantly enhance your workflow and output quality. Specialized software like Adobe Illustrator or designated DTF application can streamline the design process. These programs often come equipped with features tailored for gangsheet design, such as alignment guides, color correction tools, and the ability to manage multiple layers, ensuring that your prints turn out looking professional.

Moreover, utilizing software specifically designed for DTF printing helps in managing large print files and optimizing layouts for maximum efficiency. Effective file preparation can prevent common issues that arise during the printing process, such as overlapping designs or incorrect sizing. By taking advantage of these advanced software tools, you can monitor and fine-tune every aspect of your designs, leading to more polished results in your custom apparel projects.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it enhance custom apparel printing?

A DTF Gangsheet Builder is a specialized tool that allows users to compile multiple designs onto a single film for Direct-to-Film (DTF) printing. It enhances custom apparel printing by maximizing material usage, reducing waste, and cutting costs, while enabling vibrant, high-quality designs to be transferred onto various fabrics.

What are some tips for optimizing design layouts when using a DTF Gangsheet Builder?

To optimize design layouts in a DTF Gangsheet Builder, arrange your designs using a grid layout to maximize space, adjust sizes to fit snugly, and ensure high-resolution files (300 dpi or higher) in formats like PNG or TIFF. This ensures quality and efficiency in your custom apparel printing.

How can color calibration improve the results of DTF gangsheet design?

Color calibration is crucial in DTF gangsheet design as it ensures consistent color reproduction. By managing color profiles that correspond to your specific DTF printer and ink, you minimize color discrepancies between designs on screen and the final prints, leading to more accurate and vibrant results.

Why is conducting test prints important when using a DTF Gangsheet Builder?

Conducting test prints is vital when using a DTF Gangsheet Builder as it helps identify any potential issues with print quality or color accuracy. These preliminary runs allow you to make adjustments, troubleshoot problems, and ensure that your final custom apparel printing meets the desired standards.

What software tools can enhance the use of a DTF Gangsheet Builder for print optimization?

Software tools like Adobe Illustrator, as well as specialized DTF software, can greatly enhance the use of a DTF Gangsheet Builder. These tools help with color optimization, layout management, and file preparation, ensuring a smoother workflow and improved outcomes in custom apparel printing.

How should adhesive powder be applied for the best results in DTF printing?

For optimal results in DTF printing, adhesive powder should be applied evenly over the design during the gangsheet process. Uniform coverage is critical, as it prevents inconsistencies during the heat transfer. It’s also important to use a heat press set to the correct temperature for effective adhesion to the fabric.

| Key Components | Tips | Notes |

|---|---|---|

| Specialized DTF Printer | Maximize Space | Use a grid layout to optimize design arrangement. |

| DTF Inks | Proper File Formats | Use high-resolution formats like PNG or TIFF. |

| Transfer Film | Color Calibration | Match color profiles with printer and ink types. |

| Adhesive Powder | Conduct Test Prints | Test prints help identify and fix issues before full production. |

| Even Adhesive Layering | Leverage Software Tools | Use software like Adobe Illustrator for better design management. |

Summary

DTF Gangsheet Builder is essential for achieving the best outcomes in custom apparel printing. To harness the full potential of DTF printing, it’s important to understand the foundational elements like specialized printers and inks, as well as the crucial role of transfer films and adhesive powders. Effective utilization of the DTF gangsheet builder involves optimizing your design layouts, using appropriate file formats, and calibrating colors accurately, which together lead to vibrant and consistent prints. Conducting thorough test prints ensures that any potential issues are resolved prior to any larger production runs. Furthermore, leveraging specialized software tools can streamline the design process, making it easier to manage layouts and optimize colors effectively. Following these strategies will enable you to create stunning custom apparel that captivates your audience and elevates your brand.