The DTF printing process, or Direct to Film printing, is rapidly transforming the landscape of custom apparel by enabling designers to achieve vibrant and high-quality prints with striking clarity. This innovative technique leverages state-of-the-art heat transfer printing technology to transfer intricate designs directly onto a special film before applying them to fabric. Whether you’re a small business owner looking to stand out in a competitive market or a DIY enthusiast eager to showcase your creativity, mastering DTF printing offers numerous advantages such as speed, detail, and versatility across different materials. The process not only enhances the visual appeal of your garments but also guarantees durability and longevity that your customers will appreciate. Dive into the world of vibrant garment printing and discover how the DTF printing process can elevate your custom apparel creations to a whole new level.

What is often referred to as Direct to Film printing (DTF) has revolutionized the way custom designs are transferred onto fabrics. This modern approach to heat transfer printing simplifies the task of creating detailed and colorful graphics, making it an attractive option for those involved in the apparel industry. Utilizing unique film technology, the process seamlessly applies designs onto a variety of textiles, from cotton to polyester blends. By understanding the key advantages of this method, such as its efficiency and the ability to produce vivid colors, you can effectively cater to your clientele’s needs. This comprehensive guide will help you navigate through the essential steps required to master the DTF printing technique, ensuring your designs are not just visually striking but also long-lasting.

What is DTF Printing?

Direct to Film (DTF) printing is revolutionizing the world of custom apparel by offering an innovative approach to garment printing. Unlike traditional methods such as screen printing, DTF printing leverages specialized technology to print vibrant designs directly onto a film before transferring them onto fabric. This method has gained traction due to its versatility; it is suitable for various materials, including cotton, polyester, and blends, allowing for a broad spectrum of customizations. In addition to its adaptability, DTF printing provides stunning color fidelity and detail, making it a preferred choice among designers looking to make a statement.

Furthermore, DTF printing distinguishes itself by utilizing eco-friendly water-based inks, which not only ensures vibrant output but also promotes sustainability in the printing industry. As consumers become increasingly conscious about the environment, adopting methods like DTF can enhance brand image and attract eco-conscious customers. Its advantages extend beyond aesthetics, making it an efficient and practical solution, especially for small businesses looking to offer unique, high-quality apparel without the usual time-consuming setup associated with traditional printing methods.

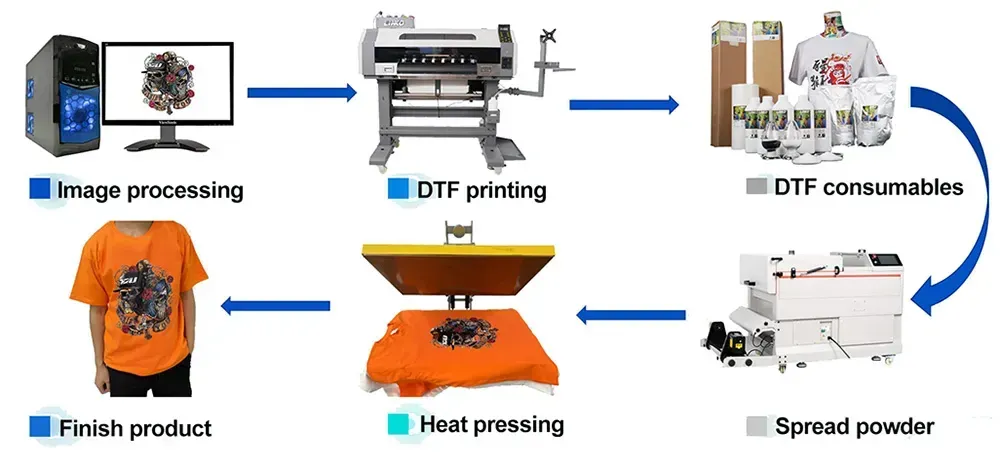

The Detailed DTF Printing Process

The DTF printing process encompasses several key steps that ensure high-quality output. It begins with design creation, where designers can unleash their creativity using software like Adobe Illustrator or Photoshop, optimizing images for vibrant results. After finalizing the design in the correct dimensions and color profiles, it transitions to the film printing phase. Utilizing specialized DTF printers, the design is then printed onto the DTF film with water-based inks, setting the stage for a successful transfer.

Once the film is printed, the next step involves applying adhesive powder directly onto the wet print, ensuring even coverage for maximum adherence. Following this, curing the adhesive is crucial; whether using a heat tunnel or heat press, achieving the correct temperature is essential for durability. Once cured, the film is aligned carefully onto the garment where heat and pressure facilitate the transfer, ultimately leading to the moment of truth – peeling off the film to reveal a vibrant print that adheres impeccably to the fabric. Each step is vital in the DTF process, contributing to the overall success of the final product.

Advantages of DTF Printing

DTF printing offers numerous advantages that set it apart in the custom apparel industry. One of the foremost benefits is its ability to produce vibrant colors and intricate designs, which are crucial for compelling fashion statements. The use of water-based inks also contributes to a softer feel on garments, ensuring comfort without compromising on the visual appeal. Moreover, the quick turnaround time for small batch orders makes DTF printing incredibly efficient, allowing businesses to meet customer demands promptly.

Beyond aesthetics and efficiency, DTF printing is exceptionally versatile. It accommodates a range of materials, making it an excellent choice for various products beyond just apparel, including accessories and promotional items. This flexibility opens the door for businesses to diversify their product lines and cater to a wider audience. As customers increasingly seek customization, adopting DTF printing can significantly enhance a brand’s marketability and competitiveness in an ever-evolving landscape.

Essential Equipment for DTF Printing

To successfully embark on the DTF printing journey, investing in the right equipment is paramount. At the core of the operation is a quality DTF printer, designed specifically for this technology. These printers utilize eco-friendly water-based inks that are not only compatible with various substrates but also yield excellent color vibrancy. In addition, having a reliable heat press is crucial for the heat transfer phase, ensuring that the designs adhere properly to fabrics and withstand washing and wear.

Another important component is the DTF film itself, which should be selected based on the specific requirements of the printer and inks used. Pairing the right film with appropriate adhesive powders will enhance transfer quality, making it essential to understand material compatibility. Accessories like sifting tools for adhesive application and temperature control devices for curing can further improve the overall efficiency and quality of the printing process. By equipping oneself with solid tools and understanding their functionalities, aspiring DTF printers can ensure optimal results.

Designing for Success in DTF Printing

Creating an impactful design is the cornerstone of successful DTF printing. When crafting graphics, designers should utilize high-resolution images to ensure clarity and detail. Setting the design in CMYK mode will help in accurately predicting how colors will appear once printed, avoiding any discrepancies that can arise from using RGB settings. Additionally, designing within the correct dimensions for the target garment is essential; this ensures that the final product fits well and looks professional.

Moreover, incorporating vibrant color palettes can significantly enhance the visual appeal of the printed garment. Designers should experiment with contrasting colors to make elements pop, reflecting current fashion trends and customer preferences. The key is to balance creativity with technical criteria, ensuring that the final design not only captivates the audience but also meets the specifications necessary for a successful transfer. By honing design skills and understanding the nuances of DTF printing, creators can achieve stunning, market-ready apparel.

Tips for Troubleshooting DTF Printing Challenges

Even with the best-laid plans, issues can arise in the DTF printing process that may affect the quality of the final product. One common challenge is improper adhesion during the heat transfer phase. If the design lifts or peels away, it’s essential to check that the correct heat and pressure settings were applied. Experimenting with different temperatures and press times may be necessary to achieve optimum results. Also, ensuring that adhesive powder is applied evenly can prevent clumping and promote even adherence.

Another potential issue could be related to the quality of the film or ink used. If colors are fading or not appearing as expected, it might be time to assess the supplies. Using the right DTF film is crucial to achieving vibrant prints, and low-quality inks can lead to poor results. Keeping a consistent inventory of high-grade materials will minimize these hiccups. Finally, regular maintenance and calibration of the printing equipment are indispensable to keep the DTF printing process running smoothly and efficiently.

Frequently Asked Questions

What is the DTF printing process and how does it differ from traditional printing methods?

The DTF printing process, or Direct to Film printing, involves printing designs onto a special film before transferring them onto the fabric with heat. Unlike traditional screen printing, DTF allows for vibrant colors and detailed designs with less setup time, making it a versatile choice for custom apparel printing.

What are the advantages of using DTF printing for custom apparel?

DTF printing advantages include vibrant color output, the ability to print on various fabric types, and quicker production times compared to traditional methods. This process provides high-quality prints that are durable, making it an excellent option for custom apparel printing.

How can I create effective designs for the DTF printing process?

To create effective designs for the DTF printing process, use graphic design software and ensure your design is in CMYK color mode, uses high-resolution images (300 DPI or more), and fits the garment dimensions well. This preparation ensures high-quality results for vibrant garment printing.

What materials do I need for the DTF printing process?

For the DTF printing process, you need a DTF printer with water-based inks, special DTF film, adhesive powder, and a heat press. Each of these components is crucial for achieving the best results in custom apparel printing.

What types of fabrics are best suited for DTF printing?

DTF printing can be applied to a variety of materials, including cotton, polyester, and fabric blends. This versatility makes DTF printing a great choice for custom apparel, allowing for vibrant designs to be printed on different garment types.

How can I ensure the longevity of prints created through the DTF printing process?

To ensure the longevity of prints made with the DTF printing process, properly cure the adhesive after application and consider a second curing session. This increases the durability of the transfer, maintaining the vibrant colors and details over time.

| Step | Description | Tips |

|---|---|---|

| 1. Design Creation | Create your design using graphic design software, ensuring it fits well for the garment. | Use CMYK mode, set correct dimensions, and ensure high-resolution images (300 DPI). |

| 2. Printing the Film | Print onto DTF film with a DTF printer using water-based inks for vibrant colors. | Select the right film and adjust printer settings accordingly. |

| 3. Applying Adhesive Powder | Apply adhesive powder on the wet print to ensure good adherence to fabric. | Apply while wet and ensure even coverage without clumps. |

| 4. Curing the Adhesive | Cure adhesive by applying heat, usually around 160°C (320°F). | Check adherence quality before proceeding to transfer. |

| 5. Heat Transfer to the Garment | Transfer the cured film onto the garment with heat and pressure. | Align carefully and follow recommended heat guidelines. |

| 6. Peeling Off the Film | Allow the garment to cool slightly, then peel off the film carefully. | Inspect to ensure no blank spots are present after removal. |

| 7. Final Curing (Optional) | Perform a second curing session without the film for added durability. | Heat briefly to ensure the design is fully set and long-lasting. |

Summary

The DTF printing process is a transformative method for creating high-quality custom apparel that captivates consumers with vibrant graphics and clarity. By following the outlined steps—from designing your artwork to flawless heat transfers—a stunning garment is just a print away. DTF printing stands out not only for its efficiency and versatility across different fabric types but also for enabling creators to experiment with rich colors and intricate details. This modern printing technique offers both professionals and novices the opportunity to refine their craft and provide competitive products in the dynamic apparel market. Dive into the DTF printing process, and unleash your creativity while enjoying the satisfaction of producing eye-catching designs!