DTF transfers, or Direct to Film transfers, are transforming the custom printing industry with their ability to deliver vivid, high-quality designs on various fabrics. While this innovative method offers a plethora of possibilities, it can also lead to some common DTF transfer issues that can frustrate even seasoned printers. Whether you’re facing problems with adhesion, color vibrancy, or transfer durability, knowing how to troubleshoot DTF transfers is essential for achieving the best results. This guide will not only highlight typical DTF transfer problems but also provide effective tips and tricks for fixing DTF transfers to enhance your printing experience. With a few adjustments and keen insights, you can overcome these hurdles and ensure your projects shine with excellence.

When we talk about DTF transfers, we refer to a cutting-edge printing technique that utilizes Direct to Film technology to create striking designs on textiles. Often associated with innovative garment printing, this method allows for seamless application of artwork onto a variety of surfaces. However, just like other printing processes, it can introduce challenges such as print fades or poor adhesion. By understanding the intricacies of this technique, or what some might call film transfers or the DTF printing method, you’ll be better equipped to solve issues and enhance your results. Join us as we delve into troubleshooting strategies and DTF printing tips that will elevate your craft.

Understanding the Basics of DTF Transfers

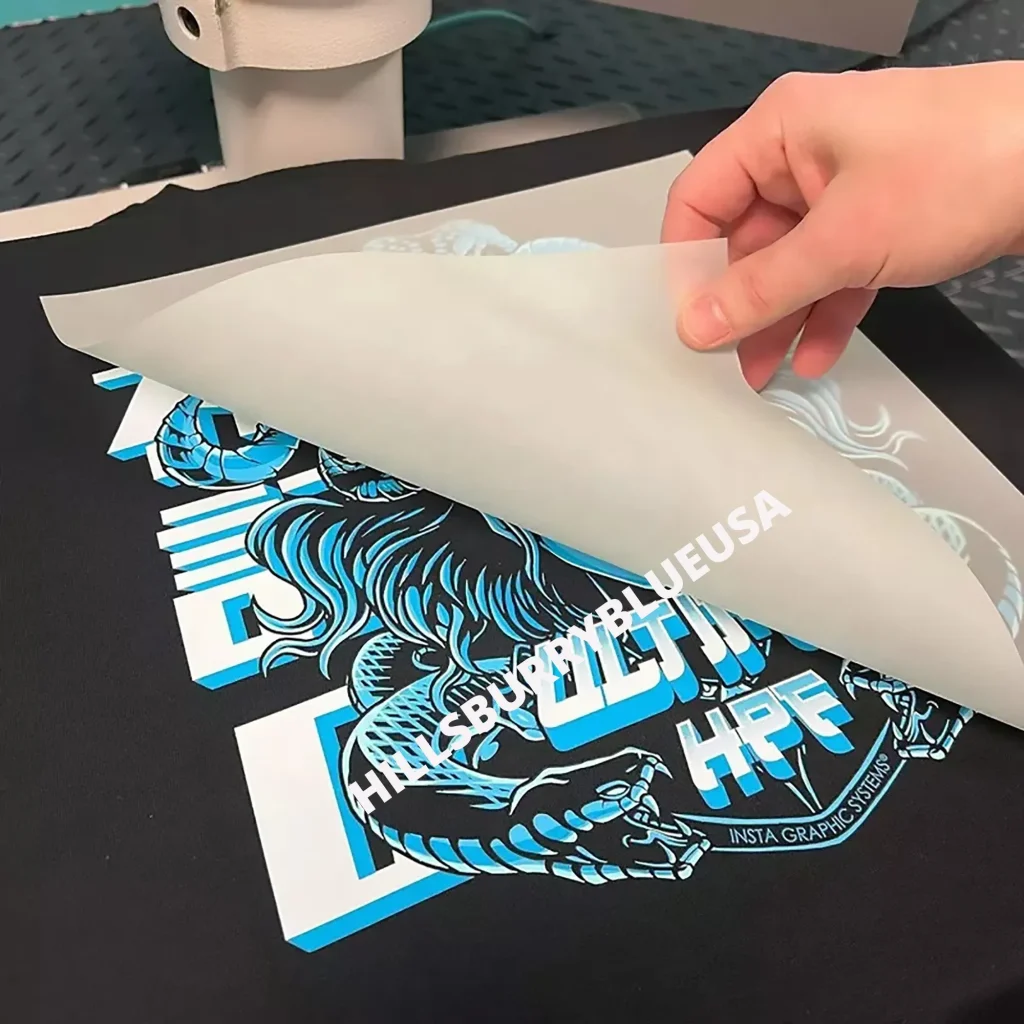

Direct to Film (DTF) transfers represent a significant advancement in the realm of custom printing, merging art and technology seamlessly. This innovative technique involves printing designs onto a special film that can then be transferred onto various fabrics using a heat press. The result is a strikingly vivid image that adheres well to the material, whether it be cotton, polyester, or blends, making it an ideal choice for numerous applications, ranging from fashion apparel to promotional merchandise.

To fully leverage the benefits of DTF printing, it is crucial to grasp the fundamentals of the process. Each stage, from selecting the right materials to the final transfer action, plays a vital part in the quality of the outcome. Understanding your heat press settings, the compatibility of inks with the substrate, and the overall workflow can significantly enhance the durability and vibrancy of printed images.

Common DTF Transfer Issues and Effective Solutions

Despite its advantages, several common DTF transfer problems can impede production quality. Issues such as poor adhesion, color fading, or transfer cracking often arise and can be particularly frustrating for beginners. For instance, if the transfer does not stick to the fabric adequately, it may be due to incorrect heat settings or insufficient pressure applied during the pressing stage.

To combat these problems, users must familiarize themselves with troubleshooting techniques that address each specific issue. Adjusting temperature and time settings or ensuring the proper distribution of adhesives can significantly improve adhesion. Moreover, utilizing high-quality inks and executing precise printer settings can help mitigate issues related to color vibrancy, ensuring your designs pop as intended.

Tips for Fixing DTF Transfer Problems

When faced with DTF transfer challenges, knowing the appropriate fixes can save time and materials. For instance, issues like transfer cracking often occur from using excessive heat or incorrectly washing the printed fabric. Educating customers on care instructions, such as washing garments in cold water, can significantly prolong the life of the transfer.

Moreover, adopting flexible transfer films can facilitate better stretching without compromising the integrity of the design. This approach not only enhances the longevity of the transfers but ensures customer satisfaction, leading to repeat business and positive word-of-mouth.

Essential DTF Printing Tips for Success

To achieve optimal results with DTF transfers, implementing a set of best practices is crucial. Regular maintenance of printing equipment, including thorough cleanings of the printer heads and heat presses, can prevent issues such as ink clogs that hinder the printing quality. Additionally, pre-testing settings on different fabrics helps in calibrating the equipment for specific materials, ensuring that each transfer is vibrant and durable.

Conducting regular quality control checks during production can catch potential issues early, allowing for immediate adjustments. This proactive approach minimizes wasted materials and improves the overall efficiency of the printing process. By focusing on these essential aspects, you can create consistently high-quality DTF transfers.

Exploring Resources for Advanced DTF Printing

For those looking to deepen their understanding of DTF transfers, exploring a variety of resources can be incredibly beneficial. YouTube tutorials offer visual demonstrations that can elucidate complex processes, while dedicated blogs on textile printing continually update readers about the latest trends and advancements in DTF technology. These platforms often feature expert tips and troubleshooting advice that can enhance your practice.

Additionally, engaging with online forums, such as those on Reddit, can provide valuable anecdotal insights from fellow printing enthusiasts. Sharing experiences with the community opens up discussions about common challenges faced during DTF transfers and the success stories of overcoming them, fostering an environment of learning and growth.

Maintaining Your DTF Transfer Equipment

Regular maintenance of your DTF transfer equipment is crucial for achieving consistently high-quality results. Keeping your heat press and printing machines in optimal condition will prevent many common issues associated with DTF printing. Routine cleaning helps avoid ink clogs, maintains precise temperature control, and ensures that every transfer is applied uniformly.

Moreover, checking for wear and tear on components such as heat press pads or printer nozzles should be standard practice. A well-maintained machine not only enhances the quality of the transfers but also extends the lifespan of your equipment. This attention to detail equates to better performance and fewer frustrations in your printing journey.

Frequently Asked Questions

What are the most common DTF transfer issues and how can I fix them?

Common DTF transfer issues include poor adhesion, color fading, transfer cracking, white borders, and curing problems. Fixing DTF transfers often involves adjusting heat press settings, ensuring even pressure, using high-quality inks, and maintaining proper washing techniques.

How can I prevent poor adhesion when using DTF transfers?

To prevent poor adhesion with DTF transfers, increase pressing time and temperature to the recommended range of 320°F to 350°F. Additionally, ensure you apply even pressure during the heat transfer process.

What should I do if my DTF transfers have color fading or dullness?

If you experience color fading or dullness in your DTF transfers, switch to high-quality, pigment-based inks specifically designed for DTF printing and check that your printer settings are calibrated correctly to match the substrate.

What causes white borders around DTF transfers and how can I avoid them?

White borders around DTF transfers are often caused by misalignment during printing. To avoid this, ensure proper alignment of the transfer design before pressing and utilize borderless printing options in your printer settings.

How can I fix transfer cracking in DTF prints?

Transfer cracking can occur due to excessive stretching of the fabric or improper washing. To fix this, advise that items are washed in cold water and consider using flexible transfer films that reduce cracking.

What are some tips for ensuring successful DTF transfers?

To ensure successful DTF transfers, regularly maintain your printing equipment, conduct pre-testing of settings on different fabrics, and perform quality checks on each transfer to catch issues early.

| Key Point | Description |

|---|---|

| Understanding DTF Transfers | DTF printing involves transferring designs from film to fabric using heat and pressure, allowing for detailed and colorful prints. |

| Poor Adhesion | Caused by improper heat press settings or pressure; solutions include adjusting temperature (320°F-350°F) and ensuring even pressure. |

| Color Fading or Dullness | Often due to low-quality inks; solutions involve using high-quality, pigment-based inks and calibrating printer settings. |

| Transfer Cracking | This occurs from fabric stretching or high-temperature washing; wash in cold water and use flexible transfer films. |

| White Borders Around Transfers | Misalignment during printing leads to borders; solutions include ensuring proper alignment and using borderless settings. |

| Curing Issues with Powder | Bubbling and uneven finishes result from improper curing; distribute powder evenly and adhere to manufacturer guidelines. |

| Best Practices | Regular maintenance, pre-testing settings on various fabrics, and conducting quality control inspections prevent issues. |

Summary

DTF transfers are an innovative method for achieving vibrant designs on textiles, but they can come with their own set of challenges. By understanding the common issues like poor adhesion and color fading, and implementing targeted solutions, you can significantly enhance your DTF printing process. Regular maintenance and adhering to best practices can ensure your DTF transfers remain successful, leading to longer-lasting and high-quality outputs.