Understanding how UV DTF works is essential for anyone interested in contemporary printing methods, particularly in the realm of custom printing solutions. UV Direct to Film (DTF) printing employs cutting-edge UV printing technology that revolutionizes the way designs are transferred onto various substrates. This innovative approach combines the flexibility of Direct to Film techniques with the durability offered by UV-curable inks, resulting in vibrant and long-lasting prints. As a versatile option, UV DTF printing can be applied to textiles, plastics, metals, and even wood, catering to a wide range of creativity and business needs. Dive into this guide to explore the intricate process and benefits that UV DTF printing brings to the table, and discover why it has become a favorite among artists and manufacturers alike.

When it comes to modern printing techniques, comprehending the functionality of ultraviolet Direct to Film printing is paramount. This advanced process marries traditional transfer methods with ultraviolet curing technology, ensuring exceptionally high-quality outputs. The unique capability to print directly onto various materials enhances its appeal, allowing for a diverse range of applications. By utilizing specialized ultraviolet inks, this procedure not only promises sharp and vivid designs but also boosts the longevity of prints, thereby meeting the demands of industries seeking reliable and durable marking solutions. Whether you refer to it as UV DTF or explore its alternatives like UV transfer printing, the principles and benefits remain significantly impactful in today’s custom printing landscape.

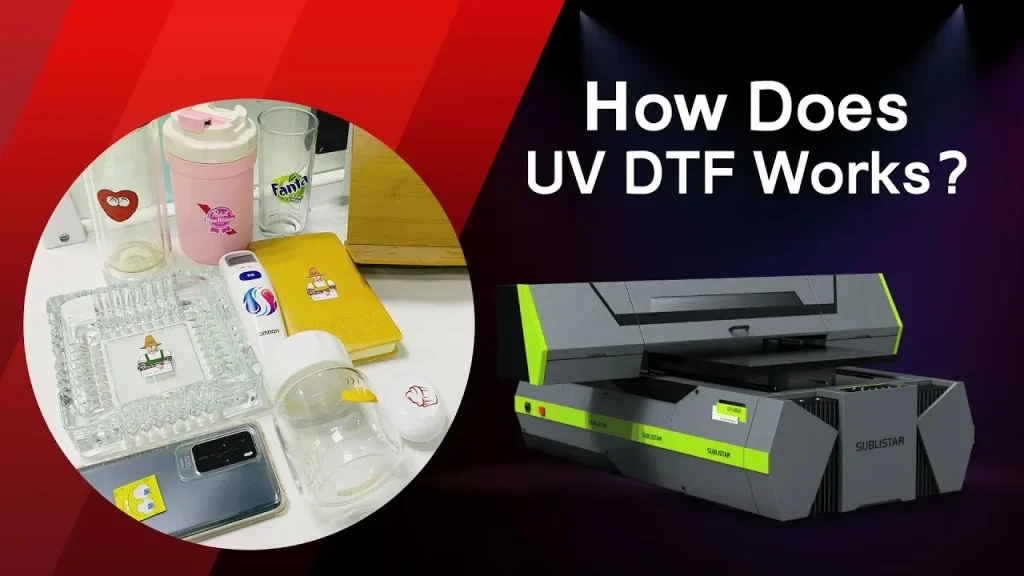

Understanding UV DTF Printing Technology

UV Direct to Film (DTF) printing is a cutting-edge technology that leverages UV printing methods to produce vibrant, high-resolution images on a myriad of substrates. Unlike traditional DTF, which relies on water-based inks, UV DTF utilizes specialized UV-curable inks that harden instantly when exposed to UV light. This results in striking print quality that is both durable and richly colored, ideal for everything from textiles to metal surfaces. The versatility of UV DTF printing makes it a preferred choice among businesses looking to offer customized printing solutions that meet diverse consumer needs.

One of the key benefits of UV DTF printing is its ability to print on various substrates with ease. This technology is not limited to paper or fabric; it can also effectively print on tough materials like plastic, leather, and even wood. This broad substrate compatibility opens up a world of possibilities for designers, brands, and hobbyists, allowing them to explore creative avenues that were previously difficult or impossible. Consequently, the growing interest in UV DTF printing reflects an increase in demand for unique, tailored print solutions across multiple industries.

The Step-by-Step Guide to UV DTF Printing

Understanding how UV DTF works involves looking at its clearly defined steps from design to final product. The process begins with the creation of a digital design, which is crafted using graphic design software. Here, designers can manipulate colors, incorporate images, and create text that suits the final printed output. This digital file will be printed onto a specialized transfer film, which is integral to achieving the desired print quality. High-resolution design files ensure that the UV DTF process captures the intricate details of the artwork, setting the stage for stunning final products.

Next, the printing process involves using a UV printer to apply UV-curable inks onto the transfer film. Unlike traditional ink, these UV inks remain in liquid form until cured by UV light, allowing for precise color application and a wide range of shading options. The curing process is instantaneous, resulting in a quick turnaround and allowing for extensive production runs without compromising print quality. This meticulous approach enhances the durability of prints, making them resistant to scratching, fading, and washing, which is crucial, especially for apparel and promotional items.

Curing and Transferring UV DTF Prints

Curing is one of the most vital stages of the UV DTF printing process. Once the design is printed onto the transfer film, it’s exposed to UV light, initiating a chemical reaction that instantly hardens the ink. This immediate curing ensures that the ink adheres firmly to the film while maintaining vibrancy and clarity. Since the ink is cured on demand, businesses can produce high-quality prints without worrying about smudging or drying times, resulting in efficient production cycles. This efficiency is particularly beneficial for businesses looking to scale their operations smoothly.

Following the curing phase, the printed design is transferred to the desired substrate using heat and pressure, similar to conventional DTF methods. During this transfer, the heat activates the adhesive properties of the cured ink, ensuring a strong bond to the substrate. This means that regardless of the surface material—whether fabric, ceramic, or metal—the final product remains vibrant and long-lasting. It’s this ability to produce high-quality prints on diverse materials that positions UV DTF printing as an innovative solution in the realm of custom printing.

Recent Innovations in UV DTF Technology

The UV DTF printing industry has witnessed remarkable innovations that cater to the evolving demands of creators and businesses. Recent advancements, such as the introduction of printers capable of creating 3D textures, have expanded the capabilities of UV DTF printing. For example, the eufyMake UV Printer E1 allows for the creation of raised textures up to 5mm thick, which can be applied on various surfaces including wood and leather. Such technological breakthroughs have redefined what is achievable in personalized and custom printing.

Moreover, companies like EazyDTF are setting milestones in the industry by investing heavily in large-format DTF printing technology. This development is a direct response to growing consumer demand for high-quality, large-scale prints. These new large-format options not only enhance production capacities but also allow for a greater variety of applications, paving the way for firms to provide custom prints that meet precise market needs. As these technologies continue to advance, UV DTF printing will undoubtedly evolve further, offering even more creative possibilities.

The Impact of COVID-19 on UV DTF Printing

The COVID-19 pandemic has drastically changed the landscape of many industries, including UV DTF printing. With an increased focus on customization and durability, businesses have adapted to the demand for personalized products, leading to a notable uptick in UV DTF printing usage. As consumers sought unique items during lockdowns, this technology offered a solution that met both aesthetic and practical needs. Consequently, many businesses that previously relied on conventional printing methods have shifted towards adopting UV DTF technology to remain competitive.

Additionally, the pandemic has prompted many small businesses and creatives to invest in advanced printing equipment to cater to the growing demand. This shift signifies a democratization of access to quality printing technology, allowing independent creators to produce professional-grade prints at an affordable scale. As the industry continues to rebound and evolve in a post-pandemic world, the advancements in UV printing technology are likely to remain integral to its resurgence and growth.

Exploring the Versatility of UV DTF Printing

One of the most notable advantages of UV DTF printing is its unparalleled versatility. This technique can be used to print on an impressive array of substrates, including textiles, plastics, metals, ceramics, and more. Such adaptability makes UV DTF printing suitable for a wide range of applications, from garment printing to promotional materials. Brands in various sectors, including fashion, advertising, and decor, are increasingly utilizing this technology to create customized products that cater to specific consumer preferences, enhancing brand appeal.

Furthermore, the ability to print vibrant, high-quality designs on unconventional surfaces opens new avenues for creativity and expression. Artists and designers are no longer limited to traditional media and can explore innovative designs that challenge conventional printing boundaries. This has led to a thriving culture of experimentation where customized solutions can be realized beyond expectations. As businesses continue to seek unique and memorable products, the versatility of UV DTF printing will play a crucial role in shaping the future of personalized consumer engagements.

Frequently Asked Questions

What is the process of how UV DTF works in printing on various substrates?

UV DTF printing works through a series of steps that begin with creating a digital design, which is then printed onto a specialized UV transfer film. Using UV-curable inks, this method ensures vibrant colors and precision on different substrates, such as textiles, plastic, and metal. After printing, the film is cured using UV light, hardening the ink for durability before it’s transferred onto the chosen substrate.

How does UV DTF differ from traditional DTF printing methods?

The primary difference between UV DTF and traditional DTF printing lies in the type of ink used. UV DTF employs UV-curable inks that are cured instantly using UV light, providing vibrant and durable prints suitable for a wide range of substrates. Traditional DTF typically uses water-based inks that require a different curing process, making UV DTF faster and more versatile for customized printing solutions.

What advantages does UV DTF printing offer for custom printing solutions?

UV DTF printing offers several advantages, including exceptional print quality with vibrant colors, versatility in printing on various substrates like wood, leather, and textiles, and durability due to instant curing of UV inks. This method allows for precise designs and is ideal for businesses and hobbyists seeking high-quality, custom printing solutions that last.

Can UV DTF printing be used for textiles, and how does that process work?

Yes, UV DTF printing can be used for textiles. The process involves printing a design onto a UV transfer film, which is then cured with UV light to harden the ink. After curing, the design is transferred to the fabric using heat and pressure, activating the adhesive properties of the UV ink to ensure a strong bond. This technique ensures vibrant and durable prints on garments, making it a popular choice for custom textile printing.

What recent advancements have been made in UV DTF printing technology?

Recent advancements in UV DTF technology include innovative printers like Anker’s eufyMake UV Printer E1, which allows for the creation of 3D textures on various surfaces from home. Additionally, companies like EazyDTF are investing in large-format printing technologies to expand their capabilities, indicating a rapid growth in demand for UV DTF printing solutions and improved printing techniques.

Why is it important to understand how UV DTF works in the printing industry?

Understanding how UV DTF works is crucial in the printing industry as it highlights the benefits of using this advanced technology for high-quality prints. With its ability to print on various substrates and the durability of UV inks, businesses and creators can offer superior custom printing solutions. Knowledge of the UV DTF process also prepares individuals to leverage innovations and trends in digital printing effectively.

| Key Aspect | Details |

|---|---|

| What is UV DTF Printing? | Combines traditional DTF techniques with UV-curable inks for high-quality, vibrant prints on various substrates. |

| Step 1: Design Creation | Creation of digital designs using graphic software tailored for the print medium. |

| Step 2: Printing on Transfer Film | Printing design onto UV transfer film using UV ink that cures with UV light. |

| Step 3: Curing | UV light cures the ink on the film, resulting in durable prints. |

| Step 4: Transfer to Substrate | Transferred to desired substrates using heat and pressure. |

| Step 5: Final Touches | Additional finishing processes for durability and aesthetic enhancements. |

| Recent Developments | Increase in demand post-COVID-19 and innovations in personal UV printers. |

| Industry Growth | Investment in capacity expansion and large-format DTF technologies. |

Summary

How UV DTF works is a fascinating exploration of a modern printing technology that combines traditional methods with innovative UV curing techniques to produce stunning, durable prints. This advanced printing method not only meets contemporary consumer demands for customization but also showcases remarkable versatility across different materials such as textiles, plastics, and metals. As businesses continue to adapt to the rapid changes in the printing landscape, understanding how UV DTF works becomes essential for anyone looking to leverage its capabilities. The evolution of this technology, coupled with recent product innovations and market growth, suggests a bright future ahead, making UV DTF printing a compelling choice for professionals and hobbyists alike.