If you’re diving into the exciting realm of fabric customization, you’ve likely encountered **DTF transfers** or **Direct-to-Film Transfers**. This revolutionary printing method has gained traction among entrepreneurs and crafting enthusiasts alike because of its ability to deliver vivid, high-quality designs across a variety of materials, such as dark fabrics and cotton blends. In this detailed guide, we’ll unravel the process behind DTF transfers, the benefits of DTF printing for beginners, and essential steps for those eager to engage in the DTF printing process. By harnessing the power of DTF technology, you can produce unique creations that stand out in the market. Get ready to learn how to start DTF printing and elevate your art to new heights!

As you explore the world of fabric printing, you might be familiar with terms like **Direct-to-Film** or simply **DTF**. This method offers a fresh perspective on creating personalized apparel, making it accessible for newcomers looking to master innovative printing techniques. With its remarkable versatility, DTF technology allows for striking designs that can enhance the quality of various fabrics, particularly for custom clothing and promotional merchandise. This guide aims to provide insights into the DTF printing process, highlighting the advantages it offers while also outlining the steps for those who are just beginning their journey in this creative field. Understanding DTF transfers can pave the way for exciting opportunities in fabric design!

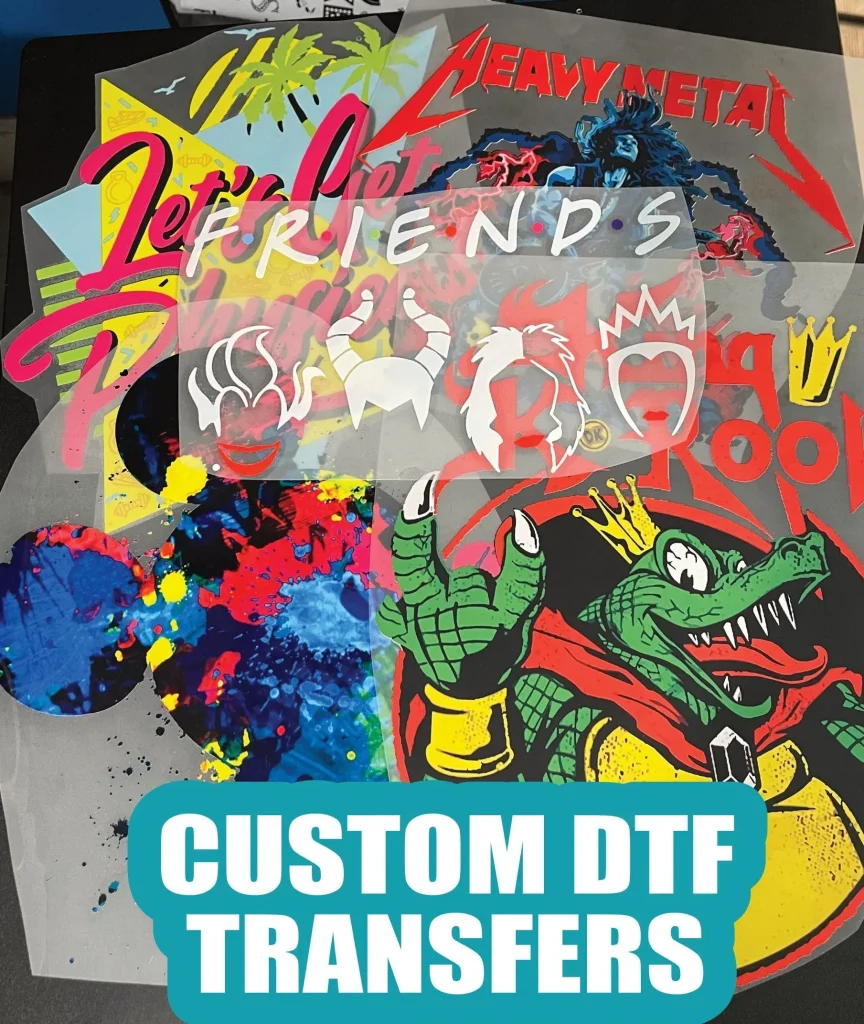

Understanding the Basics of DTF Transfers

DTF transfers, short for Direct-to-Film Transfers, are a cutting-edge technology that enables vivid and high-quality printing directly onto fabrics. This process is gaining traction among various users, from DIY enthusiasts to professional garment printers. With the versatility of DTF transfers, you can achieve vibrant results on various fabric types, including cotton, polyester, and blends. This flexibility makes it an attractive option for businesses looking to diversify their product offerings and create unique custom apparel.

The heart of DTF transfers lies in its ability to adhere to any color fabric, setting it apart from traditional printing methods. By utilizing a special film, DTF transfers allow for detailed and intricate designs that retain their color and quality over time. Additionally, the process ensures that even the finest details of a design are captured perfectly, giving users the ability to experiment with creative and complex graphics.

The Step-by-Step DTF Printing Process

To master DTF printing, understanding the workflow is crucial. The first step involves designing your artwork using graphic design software, ensuring it’s created in high resolution to maintain quality. After your design is ready, the next step is printing it onto specialized DTF film. This is done using a DTF printer with specific inks that can produce vibrant colors, allowing your designs to pop on different fabrics.

After printing, the application of powder adhesive is a vital step. The wet ink must be coated with powdered adhesive for it to stick effectively when transferred to the fabric. The curing process follows, activating the adhesive under heat. Finally, the design is transferred to the garment using a heat press, where controlled temperature and pressure ensure the design adheres securely for a long-lasting finish.

Why Choose DTF Printing?

The benefits of DTF printing are numerous and noteworthy. First and foremost, DTF transfers offer unmatched versatility. They can be applied to a range of fabrics without worrying about color limitations, which is a significant advantage for those looking to produce custom garments. DTF prints also feature vivid colors that remain vibrant through multiple washes, a testament to the durability of the process.

Moreover, DTF printing is user-friendly, making it accessible for beginners in the fabric printing industry. With manageable equipment and a straightforward process, many find DTF printing to be an excellent entry point. It also allows for high-detail printing, enabling users to bring complicated and colorful designs to life without compromising on quality.

The Learning Curve in DTF Printing

Every new printing process comes with its challenges, and DTF printing is no exception. Beginners may encounter a learning curve as they familiarize themselves with the equipment, materials, and techniques involved in DTF printing. However, the availability of ample resources, including tutorials and community groups, can help mitigate this learning hassle.

It’s crucial for beginners to understand all the steps thoroughly, from design creation to the heat transfer process. Investing time in mastering the technique can lead to impressive results, making the challenges worth overcoming. With practice, the DTF process becomes smoother, leading to high-quality prints that can expand a beginner’s creative capabilities.

Helpful Tips for Starting with DTF Printing

For those venturing into DTF printing, beginning with the right materials is essential. Make sure to invest in a reliable DTF printer, high-quality DTF film, and compatible inks. Researching and using the best powder adhesive will also contribute to your prints’ success and longevity. These materials serve as the foundation for a successful print project.

Additionally, experiment with various designs and fabric types to understand how they behave during the printing process. Each fabric may require different settings on your heat press, so keeping notes on what works best will be invaluable. As you refine your skills, don’t hesitate to explore complex designs—DTF printing accommodates artistic flair, allowing you to create standout garments.

Maintaining Quality in DTF Prints

Once you’ve successfully printed your designs, maintaining their quality is essential. Advise your clients or yourself on proper care for DTF-printed garments. They should avoid harsh chemicals, wash in cold water, and refrain from using bleach to preserve the colors and integrity of the prints.

Regularly assessing and maintaining your printing equipment will also contribute to quality prints. Cleaning the print heads and ensuring your DTF films are stored properly will extend the lifespan of your materials and enhance printing results. By following best practices in maintenance and care, you can ensure that your DTF prints remain vibrant and visually appealing for a long time.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, short for Direct-to-Film Transfers, involve printing an image onto a special film and then transferring it to fabric using heat. The DTF printing process allows for vibrant colors and intricate designs on a variety of materials, making it a popular choice for custom apparel.

What are the benefits of DTF printing compared to other methods?

The benefits of DTF printing include versatility to work on different fabric types, vibrant and long-lasting colors, ability to reproduce detailed designs, and ease of use, making it ideal for both beginners and experienced printers.

How can a beginner start with DTF printing?

To start DTF printing, beginners require materials such as a DTF printer, DTF film, powder adhesive, and a heat press. Following a step-by-step guide, they can create designs, print on film, apply adhesive, cure prints, and transfer them onto garments.

Are there any disadvantages to using DTF transfers?

Yes, the disadvantages of DTF transfers include the initial equipment costs, a learning curve for beginners, and potential durability issues if best practices are not followed during the printing process.

What should I consider when selecting materials for DTF printing?

When selecting materials for DTF printing, consider the type of DTF printer and inks, the quality of DTF film, and the appropriate powder adhesive. It’s important to match these materials to the fabric type for optimal results.

How do I care for DTF printed garments?

To care for DTF printed garments, wash in cold water, avoid bleach, and consider air drying to maintain the quality and longevity of the prints. Proper care instructions can help customers keep their items looking new.

| Key Points | Description |

|---|---|

| What are DTF Transfers? | DTF transfers are a fabric printing method that involves printing an image onto a film and transferring it onto various fabrics. |

| DTF Printing Process | The process includes design creation, printing on film, applying powder adhesive, curing, and heat transfer to the garment. |

| Advantages of DTF Transfers | Advantages include versatility across fabric types, vibrant color outputs, ability to reproduce intricate designs, and ease of use for beginners. |

| Disadvantages of DTF Transfers | Considerations include high equipment costs, a possible learning curve, and potential durability issues compared to other methods. |

| Getting Started | Beginners need specific materials, such as a DTF printer, DTF film, powder adhesive, and a heat press. A step-by-step approach is recommended. |

Summary

DTF transfers are an innovative solution for fabric printing that offers incredible versatility and high-quality results for various garment types. This guide provides a deep dive into the DTF printing process, highlighting its benefits and drawbacks while equipping beginners with the necessary steps to succeed in their printing endeavors. By embracing DTF transfers, you can unleash your creativity and produce unique, vibrant designs that cater to diverse customer needs. The accessibility of this technology makes it a valuable addition to any fabric printing venture.