In the ever-evolving landscape of custom printing, DTF transfers have emerged as a groundbreaking innovation that offers businesses an edge over traditional printing techniques. Direct-to-Film (DTF) printing stands out by enabling vibrant designs and swift production, making it a favorite among small business owners. Unlike conventional methods such as Screen Printing and Direct-to-Garment, DTF technology provides unparalleled versatility, allowing businesses to cater to diverse customer demands with ease. The benefits of DTF printing are not just limited to efficiency; they also encompass cost-effectiveness and superior print quality, making it a compelling choice for modern enterprises. In this blog, we will delve into the distinct advantages of DTF transfers and how they reshape the printing technology landscape.

As advancements in printing technology reshape the market, the term “Direct-to-Film prints” has gained traction among entrepreneurs seeking to enhance their custom printing solutions. This innovative method, often referred to as DTF printing, offers key advantages that set it apart from traditional approaches like Screen and Sublimation printing. With its ability to produce high-quality images on various materials and streamline production processes, this modern technique addresses the increasing consumer demand for personalized products. Embracing DTF transfers can significantly improve a company’s output while minimizing costs, reflecting the ongoing shift towards more efficient and flexible printing solutions. In this discussion, we will explore how DTF printing not only meets but exceeds the expectations of today’s market.

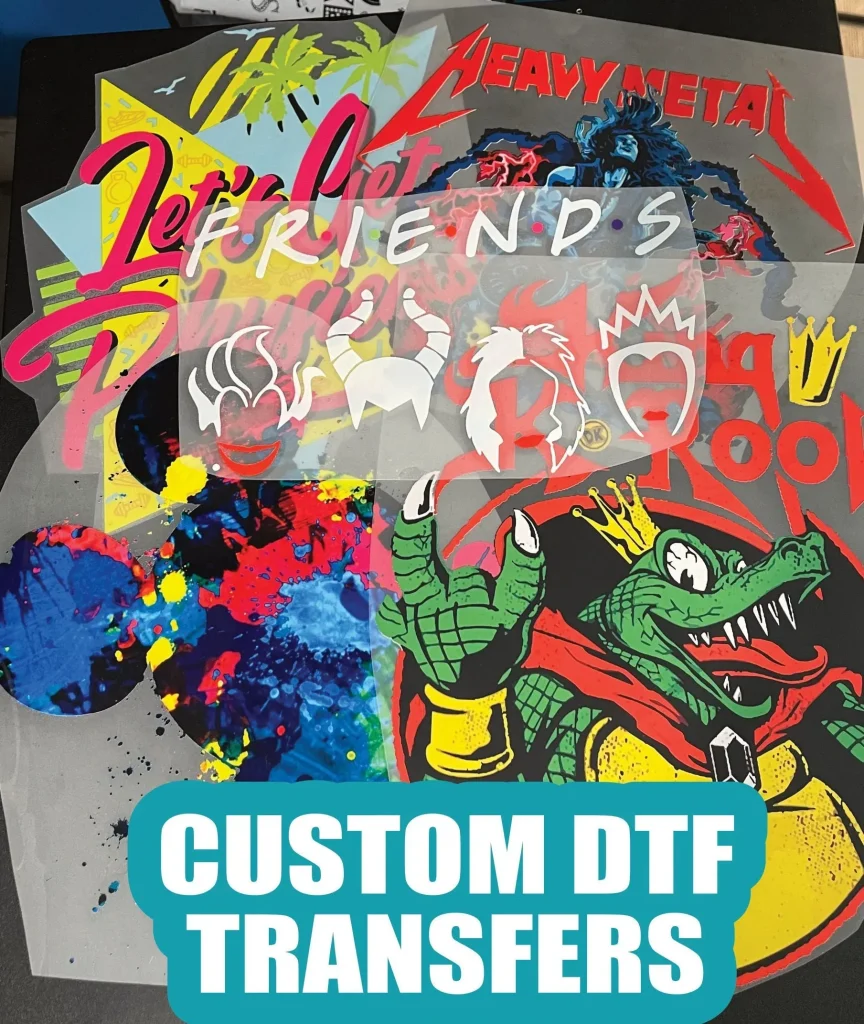

The Rise of DTF Transfers in Custom Printing

DTF transfers are revolutionizing the custom printing industry, offering a standout solution that blends quality with affordability. As small businesses increasingly seek to differentiate themselves in a crowded marketplace, DTF technology emerges as a compelling alternative to traditional printing methods. The flexibility of DTF printing allows for vibrant colors and intricate designs that cater to the evolving tastes of consumers, capturing attention and driving demand.

Moreover, the rapid growth of DTF transfer technology is indicative of changing market preferences. Brands striving for uniqueness can leverage DTF’s ability to print on various fabrics, including cotton, polyester, and blends. This versatility not only expands product offerings but also allows for faster turnaround on custom orders, aligning with the growing consumer demand for personalization.

Benefits of DTF Printing Over Traditional Techniques

One significant advantage of DTF printing is its cost efficiency compared to traditional methods such as screen printing and sublimation. While screen printing often involves high setup costs and limitations regarding color options, DTF printing requires less initial investment and allows for multi-color prints without the need for multiple screens. This accessibility empowers small businesses to offer high-quality custom prints at competitive prices.

Additionally, DTF printing eliminates many common challenges faced by traditional printing techniques. The need for special inks and pretreatment processes is reduced, simplifying the printing process. As a result, businesses can save time and resources while enhancing their production capabilities, allowing them to respond swiftly to market demands and customer inquiries.

The environmental benefits associated with DTF printing cannot be overlooked either. As consumers become more conscious of their purchasing decisions, the use of eco-friendly inks and minimal waste production are attractive selling points for businesses. By adopting DTF technology, printers can position themselves as environmentally responsible brands and appeal to a more sustainable-minded audience.

Technological Advancements in DTF Printing

DTF printing continues to evolve with advancements in technology, making it an even more attractive option for businesses. Recent innovations have led to improvements in print quality, particularly in color vibrancy and durability. This is a game-changer for brands seeking high-quality outputs that can withstand washing or wear, providing customers with value they can trust.

Moreover, the development of new DTF printers equipped with the latest technology enhances production speed and efficiency. Businesses can now handle larger volumes of orders without compromising on quality, fulfilling customer requests quickly and effectively. This capacity for growth and adaptability is essential for small businesses competing in a fast-paced market.

Understanding the DTF Printing Process

To fully appreciate the benefits of DTF printing, it’s essential to understand its unique production process. DTF printing involves printing designs onto a special film which is then transferred onto the garment using heat. This method allows for intricate and detailed designs to be printed across a variety of materials, surpassing the capabilities of traditional methods like DTG and screen printing.

The process not only offers unparalleled design flexibility but also significantly reduces the time from concept to finished product. With DTF, businesses can quickly adapt their offerings to meet changing customer preferences and trends, optimizing their production strategies to capture a larger market share.

Market Trends Favoring DTF Technology

Current market trends clearly indicate a shift towards customization and personalized products. Consumers are increasingly inclined to seek out unique items that reflect their individuality, and DTF printing caters perfectly to this demand. As small businesses invest in DTF technology, they can offer customized options that resonate with customers, leveraging this growing trend for greater profitability.

Additionally, the rise of online platforms enables businesses to reach wider audiences than ever before. DTF printing aligns seamlessly with e-commerce trends by allowing for on-demand production and rapid fulfillment of customized products, positioning small businesses to benefit from shifting consumer purchasing behaviors.

Why Choose DTF Over Other Custom Printing Methods?

Choosing DTF printing over other custom printing methods presents numerous advantages worth considering. First and foremost, the cost-effectiveness of DTF allows businesses to maximize profit margins without sacrificing quality. Unlike traditional printing methods that require extensive labor and costly materials, DTF reduces overhead costs, making it an attractive option for startups and small businesses.

This method also lends itself to quicker production cycles, which is crucial in today’s on-demand market. DTF printing’s ability to handle a variety of materials and produce vibrant, detailed designs means that businesses can satisfy trends rapidly, whether it’s for promotional events, custom merchandise, or seasonal lines.

Frequently Asked Questions

What are the benefits of DTF printing compared to traditional printing techniques?

DTF printing offers several benefits over traditional printing techniques, including cost efficiency, versatility across different materials, and superior print quality. Unlike methods like screen printing or DTG, DTF can easily handle various fabric types and deliver vibrant colors, allowing businesses to meet diverse customer demands more effectively.

How does DTF transfer technology improve custom printing capabilities?

DTF transfer technology significantly enhances custom printing capabilities by allowing for detailed multi-color designs on various fabrics. This method offers a quicker turnaround time for custom orders and requires less setup, making it perfect for small businesses looking to capitalize on the growing demand for personalized products.

Can DTF printing be used on different types of fabric?

Yes, DTF printing is highly versatile and can be used on multiple fabric types, including cotton, polyester, and blends. This flexibility enables businesses to create customized prints on a wider range of products compared to traditional printing techniques, which may be limited to specific materials.

What is the typical investment needed to start a DTF printing business?

Starting a DTF printing business typically requires a lower initial investment in equipment compared to traditional methods like screen printing. DTF printers are designed to be cost-effective, allowing small business owners to enter the custom printing market without significant financial burden.

What advancements in DTF printing enhance print quality?

Recent advancements in DTF printing technology, such as improved color vibrancy and UV DTF capabilities, have enhanced print quality. These innovations provide businesses with the ability to produce bright and detailed prints that appeal to customers, ensuring high-quality output that stands out in the competitive market.

Is DTF printing an environmentally friendly option?

Yes, DTF printing is considered an environmentally friendly option as it often uses eco-friendly inks and produces minimal waste. This sustainability aspect can attract consumers who prefer ethical and eco-conscious products, setting your business apart in today’s market.

| Aspects | DTF Transfers | Traditional Printing Methods |

|---|---|---|

| Market Launches | Emerging technologies like DTFPrinter enhance customization options. | Established techniques like screen printing face limitations. |

| Technological Innovations | Enhanced color vibrancy with UV DTF technology. | Standard CMYK processes limit color output. |

| Versatility | Compatible with various fabric types. | Limited to specific fabric types (e.g., polyester for sublimation). |

| Cost Efficiency | Lower startup costs for equipment. | Higher initial investment required for equipment. |

| Consumer Demand | Increasing demand for customizable products. | Standard prints do not cater to high customization demands. |

| Sustainability | Utilizes eco-friendly inks and generates minimal waste. | May not prioritize ecological considerations. |

Summary

DTF transfers are revolutionizing the custom printing industry by offering businesses a more profitable and efficient alternative to traditional printing techniques. As the printing landscape evolves, DTF technology not only meets the demands for high-quality and customizable products but also aligns with the growing consumer preference for sustainable practices. This innovative method allows small businesses to maximize their profits while maintaining competitive quality, thus positioning them for success in a dynamic market.